Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

- Messages

- 5,703

- Reactions

- 6,597

I used a band saw on my last one

Staff Member

Gold Supporter

Bronze Lifetime

- Messages

- 23,407

- Reactions

- 112,107

Yes , I would and have done it.

Just as you noted , be sure to "dress up" the ridge.

Andy

Just as you noted , be sure to "dress up" the ridge.

Andy

Staff Member

Gold Supporter

Bronze Lifetime

- Messages

- 23,407

- Reactions

- 112,107

Thats what I did on the few that I have done.

Add a bead sight and you are good to go.

Andy

Add a bead sight and you are good to go.

Andy

- Messages

- 1,405

- Reactions

- 1,801

Port a band  or so I've heard

or so I've heard

Diamond Lifetime

- Messages

- 6,124

- Reactions

- 13,918

I would take it real easy and crank the handle in real slow, You can swage the material down quite a bit reducing the ID of the bore significantly. If you do it in very small steps it would minimize it.

Member 34319

- Messages

- 17,146

- Reactions

- 37,070

Tried this on a H&R a while back. The metal was too hard. Ended up using an end mill to cut the barrel. Perfectly straight that way.

- Thread Starter

- #10

Yeah. I've used the pipe cutters for years. The hardness of the barrel, definitely defines a slow process. Tighten enough to grab hold, square, then a couple revolutions around the barrel. Add 1/4-1/2 turn to cutter, twice around again. Continue until cut.I would take it real easy and crank the handle in real slow, You can swage the material down quite a bit reducing the ID of the bore significantly. If you do it in very small steps it would minimize it.

All ahead "slow" Matey!

Diamond Lifetime

- Messages

- 6,124

- Reactions

- 13,918

Alright, I didn't mean to sound patronizing. I can just see someone cranking that sucker down and ending up reducing the bore size by a 1/16"

- Messages

- 11,840

- Reactions

- 11,103

I worked with a big swede that would piss off the welders by making the pipe square cranky my it down to get it done faster.I would take it real easy and crank the handle in real slow, You can swage the material down quite a bit reducing the ID of the bore significantly. If you do it in very small steps it would minimize it.

I usually use my little grinder. You can file the inside but the ridge will go away pretty fast thru firing

- Messages

- 2,794

- Reactions

- 2,489

I would favor a metal saw or carbide disc in a fixture to cut it square and clean.

Silver Vendor

- Messages

- 3,862

- Reactions

- 10,317

Do it! It kinda adds a hillbilly choke to the end of the barrel!

Bronze Supporter

- Messages

- 20,342

- Reactions

- 77,149

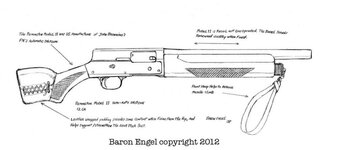

For a better finish, I use ether a ball hone for break wheel cylinders or a regular two blade hone. Just use a few drops of trany fluid and flush with solvent of your choice!I have a metal chop saw, hack saw, and a pipe cutter as shown. I figured to use the pipe cutter for the sake of a straight line cut, then a round file or reamer inside to clean it up.

When I whacked off the end of my Winchester 97 barrel I used a new tubing cutter to lightly score the barrel for marking purposes only.

Then I used a fine tooth hack saw an 1/8" above the line and then finished the rough cut with a new bastard file right down to the line.

I then used one of those stepped uni bits to lightly chamfer the bore and used the same uni bit with some 400 grit emory cloth to finish it.

Then I used a fine tooth hack saw an 1/8" above the line and then finished the rough cut with a new bastard file right down to the line.

I then used one of those stepped uni bits to lightly chamfer the bore and used the same uni bit with some 400 grit emory cloth to finish it.

Bronze Supporter

- Messages

- 5,281

- Reactions

- 10,878

Don't forget to tape the end of the barrel to keep the rollers from messing up the finish.

Bronze Supporter

- Messages

- 19,796

- Reactions

- 55,287

Nicely done!!!

I've always thought about making a SD gun out of my old 870 but cutting the barrel I wonder where to start measuring, is it where the end of the shell meets the actual barrel (the chamber) or, your thoughts?

I've always thought about making a SD gun out of my old 870 but cutting the barrel I wonder where to start measuring, is it where the end of the shell meets the actual barrel (the chamber) or, your thoughts?

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

SIG Rattler 300BLK, GBRS, Holosun, Leupold, Eotech, Midwest Industries, ETC.

- Started by notgarandthumb

- Replies: 0

-

-

-

-

Junk pile Ar15 and G3 and other misc parts

- Started by eldbillbo

- Replies: 1

-

Junk pile Ar15 and G3 and other misc parts

- Started by eldbillbo

- Replies: 0

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale