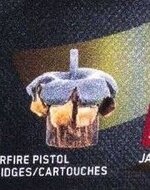

I was going through a batch of 9mm Luger military brass that have been gathered here and there. I was decapping them, getting ready to swage the primer pockets. Had one that just wouldn't cooperate.

I pulled it out to inspect. I supposed a bedan primer had got past the inspection process. .. but look at what I found. I have seen a few strange things but never something like this. I tried to call Fox Mulder from X-Files thinking it was an Alien Raygun load but he didn't answer so I am throwing it to this large group of experience re loaders.

I pulled it out to inspect. I supposed a bedan primer had got past the inspection process. .. but look at what I found. I have seen a few strange things but never something like this. I tried to call Fox Mulder from X-Files thinking it was an Alien Raygun load but he didn't answer so I am throwing it to this large group of experience re loaders.

Last Edited:

Maybe it was a 9mm secretly trying to be a pinfire round?

Maybe it was a 9mm secretly trying to be a pinfire round?