- Messages

- 2,500

- Reactions

- 5,714

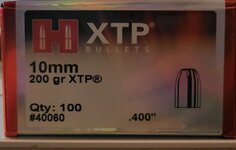

Somebody should name a press "The Real Progressive"That's the way I do it, some days I don't get any loaded and then other days I get a lot loaded. I do jump back-and-forth in between 9mm, 40 S&W, 357/38, 300 blackout and 223/556.

That's the only calibers that I load for and do not want to add anymore, I'm content.

If I had a real progressive press I wouldn't have any primers. Then I'd have to be fishing all the time instead of loading boolits.

Money