Bronze Lifetime

- Messages

- 835

- Reactions

- 859

Hello all, I am looking for input on potential home made heat sink designs for AR barrels.

I am beginning building a upper that will get abused with high round count / heavy firing schedule and have been toying with the idea of barrel heat sinks.

I am aware of the JP enterprise heat sink and am a fan of the design and also aware of its shortcomings; for this upper build accuracy is not paramount, cooling is prioritized.

Unfortunately I am going to be using a heavy chrome lined barrel that has a diameter of larger than .750 near the throat so the JP will not work. So I have turned to custom design.

Does anyone have any ideas that they have dreamed up?

I am going to be using a 1" diameter barrel and up to a 1.8" inside diameter hand guard.

I have considered scraping the whole idea and just using cheap chrome lined barrels that are disposable but figured i would pick the minds of some fellow gun nerds first.

Here's a couple links to potential ideas

everymarket.com

everymarket.com

^wrap around coil style heat sink (lacks barrel adhesion, and can't find in aluminum)

heatsinkonline.com

heatsinkonline.com

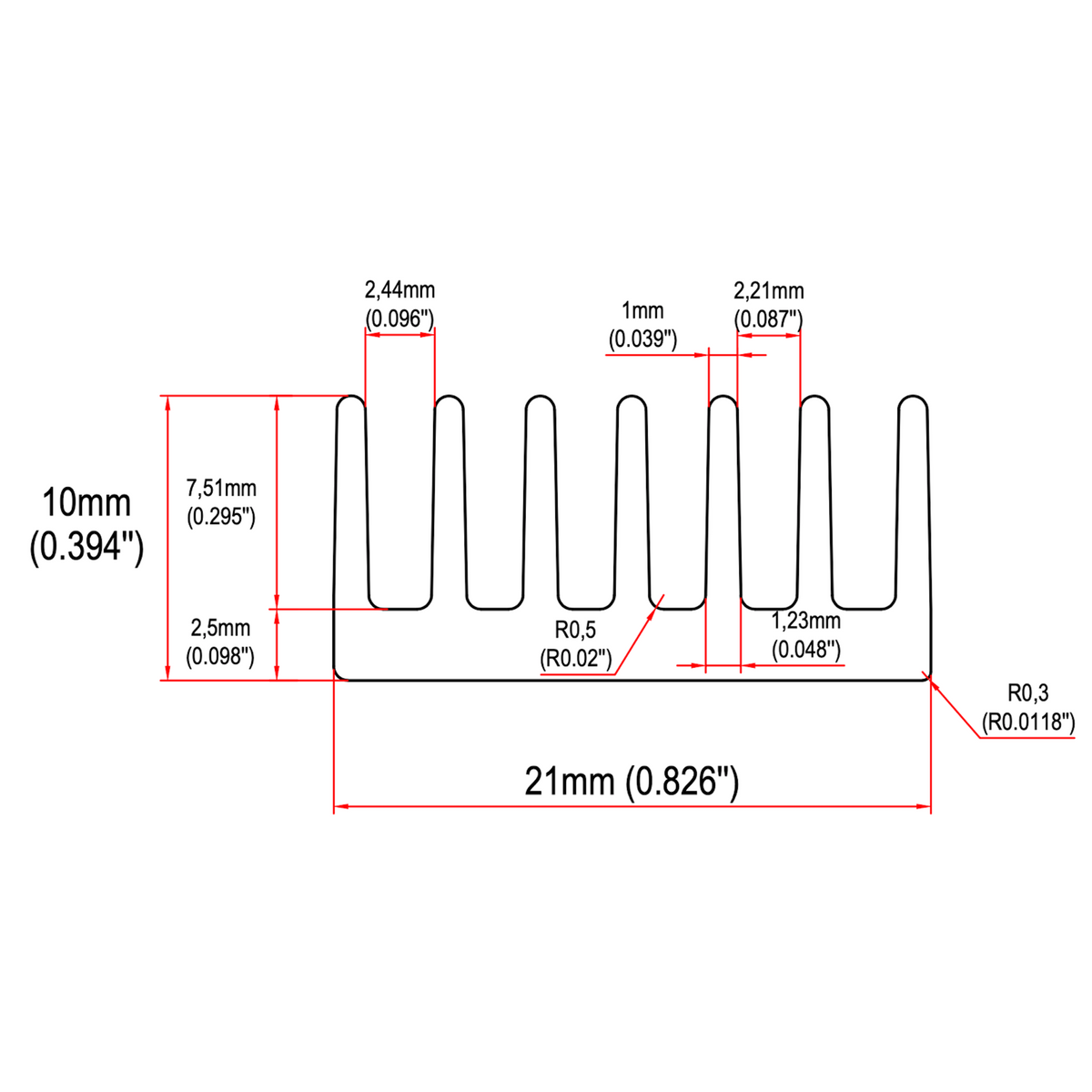

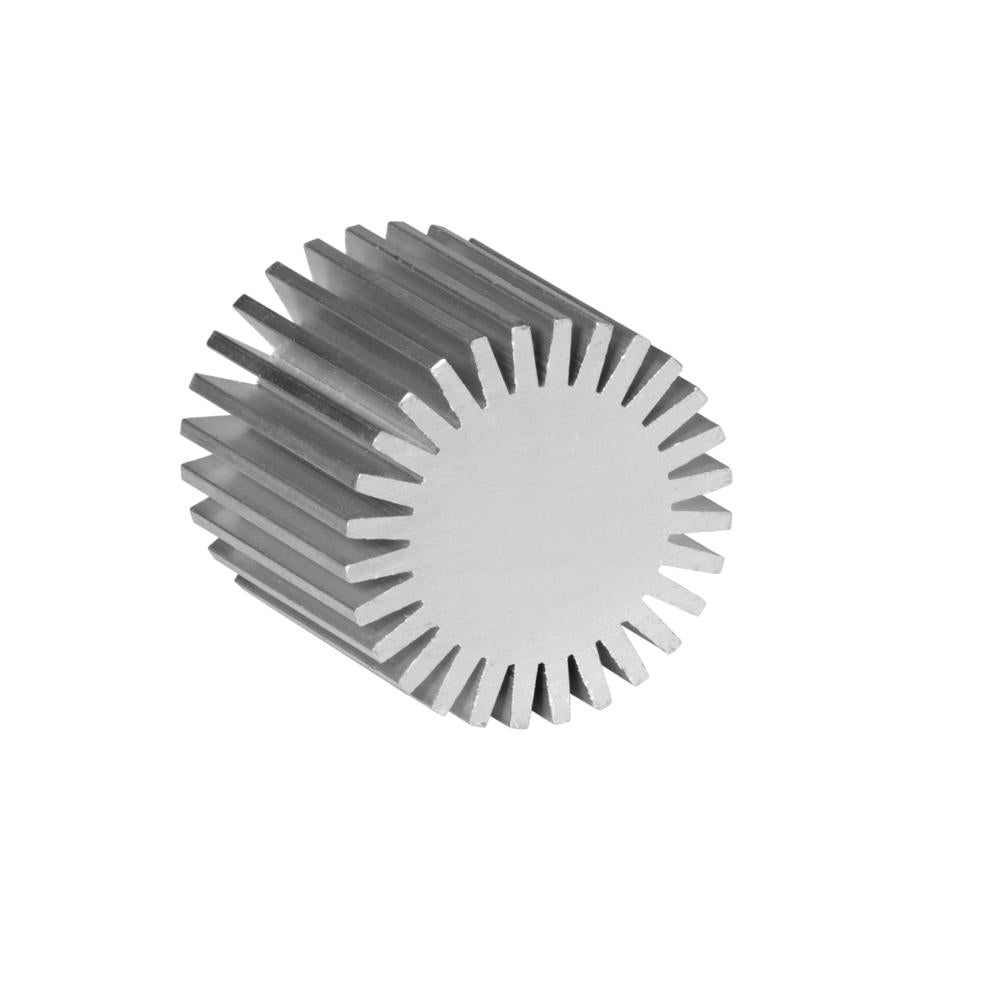

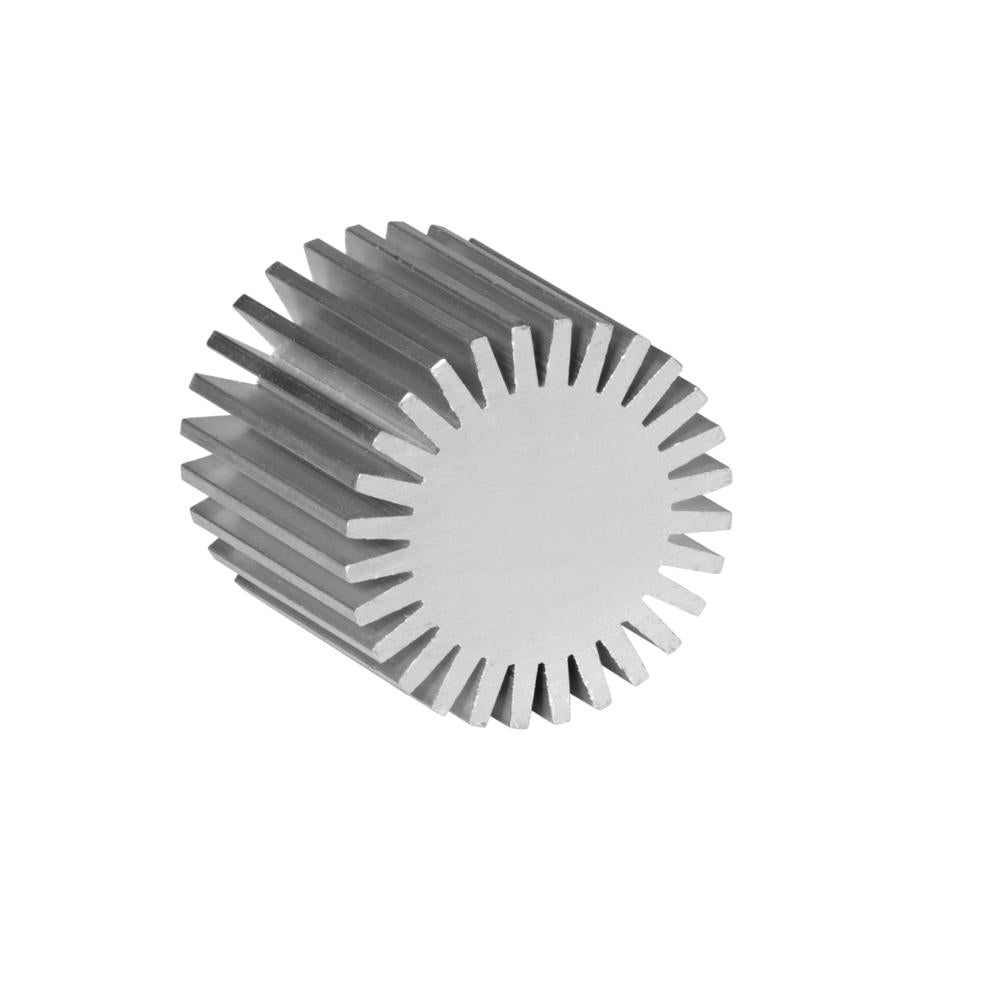

^ solid heat sink (would need to be lathed out to fit 1" barrel profile, along with some sort of clamping design)

I am beginning building a upper that will get abused with high round count / heavy firing schedule and have been toying with the idea of barrel heat sinks.

I am aware of the JP enterprise heat sink and am a fan of the design and also aware of its shortcomings; for this upper build accuracy is not paramount, cooling is prioritized.

Unfortunately I am going to be using a heavy chrome lined barrel that has a diameter of larger than .750 near the throat so the JP will not work. So I have turned to custom design.

Does anyone have any ideas that they have dreamed up?

I am going to be using a 1" diameter barrel and up to a 1.8" inside diameter hand guard.

I have considered scraping the whole idea and just using cheap chrome lined barrels that are disposable but figured i would pick the minds of some fellow gun nerds first.

Here's a couple links to potential ideas

EveryMarket

^wrap around coil style heat sink (lacks barrel adhesion, and can't find in aluminum)

Round Heatsink for LED - Diameter ⌀45mm / ⌀1.77"

SKU 2004ASL Type Round LED Heatsink Material Aluminum 6063-T5 Surface Non-Anodized (Mill Finish) Diameter (Width) ⌀45mm / ⌀1.77'' All of our Heatsink Extrusions are stocked as full length (78'' to 118'' depending on the extrusion). We cut to your specified piece length (inch/mm) per order. We...

^ solid heat sink (would need to be lathed out to fit 1" barrel profile, along with some sort of clamping design)