- Messages

- 433

- Reactions

- 263

- Thread Starter

- #21

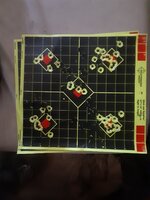

So my first attempt at setting up the dies. I picked up both RCBS and Lee dies. The Lee dies I didnt seem to have an issue with but it appears I'm buckling the cases with the RCBS dies.

First pic is the rcbs and second pic is the Lee. Both set to 1.260 coal. Suggestions? I'd prefer to use the RCBS dies.

Thanks

James

First pic is the rcbs and second pic is the Lee. Both set to 1.260 coal. Suggestions? I'd prefer to use the RCBS dies.

Thanks

James