Good on you for adopting this machine and putting it back into use. Sewing machines are a little complex, many moving parts that must work at the proper moment in relation to everything else. Unfortunately, lots of quality sewing machines have been tossed away. The problem being in our consumer country, it no longer pays to make clothing at home. It's cheaper to buy clothes from far away over the seas. The cost of yardage goods and sewing notions is prohibitive, not to mention the labor.

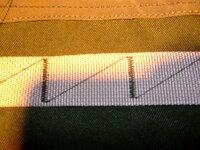

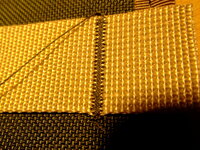

Heavy duty projects are another story. One of my good friends, now deceased, had a Pfaff industrial machine that he used for sewing automotive interiors and convertible tops. None of it looked much like Mrs. Merkt's little home Pfaff.

Some of those machines made in Japan were good items. They made some low-end cheapies too but the Singer is probably a good one. Like electronics and optical goods, making sewing machines in Japan got too expensive in relation to labor costs. They may still make some high end stuff, but I'd guess consumer grade for export is now made somewhere else.

Heavy duty projects are another story. One of my good friends, now deceased, had a Pfaff industrial machine that he used for sewing automotive interiors and convertible tops. None of it looked much like Mrs. Merkt's little home Pfaff.

Some of those machines made in Japan were good items. They made some low-end cheapies too but the Singer is probably a good one. Like electronics and optical goods, making sewing machines in Japan got too expensive in relation to labor costs. They may still make some high end stuff, but I'd guess consumer grade for export is now made somewhere else.