Bronze Supporter

- Messages

- 16,153

- Reactions

- 34,172

Bought this thing for $250 locally

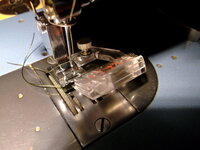

It's apparently a 1984? Singer 20U33 (marked 20-33) made in Japan, on a power table. I took the clutch off and then I tried to get the tabletop level as the previous owner had it at an angle for some reason? Maybe happened during a move or some such. Also. Previous owner used the wrong kind of needles on this machine so some adjustments and timing checks will happen when I can. Got news that we will be able to move to a ground level 3 bedroom apartment during Sept/Oct this year in the same complex, so I'm not going to lug this machine and table up to the current 2nd floor apartment only to lug it down and across

More pics and stuff next post

Serial number, according to what I could find the first 2 digits is the year, for Japanese 20U class machines?