Bronze Supporter

- Messages

- 5,282

- Reactions

- 13,699

Looks good, shoot away!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

If you do not see me online later this evening, then you would know I did a crapy job (just joking).Looks good, shoot away!

That's entirely sad. I don't know if i could support a mfgr with their head that far in the sand. I think id want one that would encourage it!They may not be sympathetic to an alchemy-based line of questioning.

Craft your question(s) carefully.

IOW, gun manufacturers want you to be using factory ammo.

So there's that.

Just a heads up!Here are my first cartridges ready to shoot. Unfortunately, after loading only 3 cartridges, I have to stop. I busted my electronic balance (dropped it on the floor and now it is not working). I am right now looking if any stores in the area have one. If not, will look to order one ASAP.

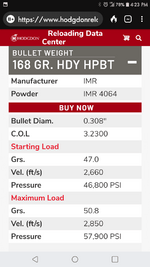

I am using old RCBS JR2 press and RCBS hand priming tool. So far, they seem to do a good job. I will shoot at least 3 of these cartridges later today (I am heading to the range around 4pm) and compare them to factory loads that shoot accurate in my rifle. The 3 live reloaded cases have 49.5gr IMR-4064 powder and Sierra Match-King 168gr bullets. According to Lyman's manual, the powder charge for this combo is 45.0gr min to 50.0 gr max. All 3 cartridges have the exact donor brass (Federal from a same factory ammo box) and the exact neck OD of .333. The bullets are all tight.

View attachment 894140 View attachment 894141 View attachment 894142 View attachment 894143

If I don't see you here later I ll just figure that you hit it out of the park on the first try and have no questionsIf you do not see me online later this evening, then you would know I did a crapy job (just joking).

Or at the tavern celebratingIf I don't see you here later I ll just figure that you hit it out of the park on the first try and have no questions

An addendum to my previous post...Just a heads up!

Watch your pressure signs closely ON THE FIRST ROUND.

My Hornady (10th ed.) Shows 51.9gn MAX @ 2800 fps. And the next lowest @ 49.6

So according to that your kinda near max. Usually you down-load 10% of MAX.

so... 51.9÷100= .519gn then × 90(%) = 46.71gn. That should be closer to your starting load.

This is for 165gn-168gn HORNADY bullets. Hornady book only lists hornady components.

You can also go to imr's website and get their data online as well so you have three sources. The more sources you can very the better. Maybe you'll get lucky and find one using your exact combo of case, powder, primer, bullet. But not likely. If that's the case id feel safe loading to within 5% or less. Maybe 3%. All depends on how much of gambler you are!

Stay safe out there!

View attachment 894170

I neck size often for my 260.When you neck size only there's no need to lube. That's one of the things I love about neck sizing. If you saw my thread from today you'll see the results of my technique.

looks good, glad everything went well. primers look great.This evening was the happiest day of my shooting ever. I finally made it to my range (Issaquah Sportsman's Club). I got stack in the traffic jam and got there 30 minutes before they were closing. I was able to just post my target and take 8 shots. I took first 5 shots with factory ammo (Rem Core-Lokt 165gr) to prime the rifle bore (I have a bad habit of cleaning my rifle after every shooting session). The scope was zeroed at 200 yards and I had no time to set it for 100 yards. After factory ammo I took 3 shots of my reloads. At first I thought my reload was bad as I could not see any 6th hole in the target. But then I looked through a 45x spotting scope and realized that my first reload shot hit the same hole where one of my Remington shots hit. I took two more shots and it was a happy ending. I grouped the 3 relaod shots under 1 inch. I am not sure it the group was 0.9 or 0.7 inches since I am not sure which hole (from the two overlapping holes) was from my reload and which from the factory ammo. Here I posted pictures of the target and I also posted a picture of reload primer. It all came far better than I could ever dream of. Upon case inspection, I could not see any syptoms of overpressure or defective priming. A new balance arrived an hour ago (I try to avoid ordering stuff from Amazon if I can buy somewhere else, but with Amazon Prime I had a new balance delivered in few hours), so I can reload more cases. I got lucky that I busted my electronic balance after only 3 cartridges were loaded. Now I do not have to try lower end charges and can keep 49.5 gr charge and can focus on bullet seating. I set the 3 loads at 3.270 OAL. I think I can try to move bullet forward. I have few rounds of factory Federal Match-Grade 168gr Sierra BTHP cartridges and they have OAL of 3.305. Originally I planed for them to be my benchmark vs. reloads, but since I did not have much time this evening I did not want to waste them on clean bore. I have 5 rounds of them. Now I need to study how much to move bullets forward on my next set of reloads. I will go in 0.005 increments. Luckily, my Foster bullet seater is one with a micro-caliber and seems to be very accurate. I tested it on few dummy rounds (seated few bullets on empty unprimed cases).

View attachment 894404 View attachment 894405 View attachment 894406

Thanks for the advice. I did notice that bullets can vary in length (about 0.008 inches) and all the difference is from the bullet tip. For the 3 reloads I picked up the exact length bullet, but for the rest of reloads I will just count on the Forster seater. Right now the seater is in the press and set from the 3 reloads. I will make tonight 8 x 6 cartridges using the exact same powder charge and bullets and will keep incrementally move up micro-adjustment (in steps of 0.005 inches). I will test these cartridges, but will save one from each 8 sets of 6 cartridges. Whichever seating wins, I will choose its saved cartridge my master cartridge and will never shoot it. Then I can measure its OGIVE and have it as my master OGIVE. Could you advice me a good gauge to use it on my caliper? As a novice to reloading, I am realizing that there are great tools, but also not that great products.looks good, glad everything went well. primers look great.

one point of note is you will get much more consistent measurements off of the ogive using the comparitor and NOT measuring off the tip of the bullet. the tips of bullets are fairly irregular. the ogive which the forester seater stem seats off of uses (or at least should use) the ogive to seat as well.

I'm surprised to read that you are assuming that your Finnish-made Tikka rifle is also made to SAAMI specifications.So far, all my resized 30-06 cases are within SAAMI specs. I primed the cases last night (will post pictures) using RCBS hand priming tool. Primer seatings look all good to my eye, but I will post some images, so more experienced reloader can give me an input. The hand priming tool worked great and was quick and easy to use, and the primer seating looks very consistent.

Your primers all seem to be set at different depths.

Welcome to the club!Now I need to study how much to move bullets forward on my next set of reloads. I will go in 0.005 increments. Luckily, my Foster bullet seater is one with a micro-caliber and seems to be very accurate. I tested it on few dummy rounds (seated few bullets on empty unprimed cases).

View attachment 894404 View attachment 894405 View attachment 894406

Sorry but this is terrible advice, seating a bullet deeper without changing anything else will INCREASE pressure.Welcome to the club!

What is the muzzle velocity of your loads?

As far as depth goes, keep in mind you might find accuracy shorter as well as longer. At this point you don't know. That's why I start as long as the rifle will let me, then I seat progressively deeper. At some point the rifle will tell me what it likes.

Here are a couple of interesting reads:

Setting Up Your Loads For Optimum Accuracy

We will show you how to set-up your loads for optimum accuracy, even if you are using a long bullet jump from a magazine.bergerbullets.com

Getting the Best Precision and Accuracy from VLD bullets in Your Rifle

VLD bullets are designed with a secant ogive. This ogive shape allows bullets to be more efficient in flight (retain more velocity = less drop and wind deflection). While this result is desirable for many rifle shooters the secant ogive on the VLD bullets produces another result in many rifle.bergerbullets.com

The second link is the process I use, at 0.040" increments. In my experience this method works with a variety of bullets, not just Bergers. That's a multiple of 8 compared to 0.005". When you find the depth that prints significantly better than the rest, then you can fine-tune up or down in smaller increments. If you limit yourself to 0.005" increments you'll be pursuing the node for years.

My goal is five-shot groups of 0.5" or less at 100 yards, with velocity on the high end, and acceptable pressure signs. I don't consider primer appearance as a sign of pressure (unless I blow a primer, of course, which hasn't happened yet) but I will pay attention to ejector marks on the base.

Start long, move one direction, larger increments. That's in line with your practice of changing one variable at a time. And yes, I was referring to a concentricity gauge. I don't use one but I hear they're great.

P