Using small rifle primers in the small pistol pocket SHOULD be just fine, the problems that could happen are only 2, that I know.

1st. primer cap could actually be to hard for your 45. If so, your out of business there,

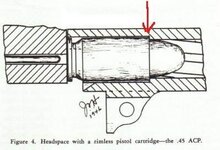

2nd, if worried, it might be to hot, just reduce 45 load by 1/2---> 1 grain powder, on 5 rds. test fire these, if no primer pressure signs, (flattened primer) then you good to go, even add back 1/2 -1 grain back to original load.. just my .o2c

With primers being so hard to come by lately I sure hope small rifle primers work in pistols because I bought 11k at Sportsman's in Redding on my way to SoCal late last week.

I've done a lot of research online and have found no general consensus. Some say no problem and I haven't bought small pistol primers in years, they work just fine in 9mm or the small primer .45ACP. Others say if one can't find hard published data (on using small rifle primers) in pistols then don't do it.

So far my plan is to load up a few 9mm and .45ACP well under the published maximums and inspect cases.