Gold Supporter

Bronze Lifetime

- Messages

- 373

- Reactions

- 320

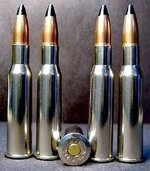

Just started reloading and have the bug to learn and try new things. I was wondering if anyone has made there own bullets and if so what they made them out of and how they worked. I've been looking at different types of metal to use all the way from solid copper to tungsten or maybe some out of the two combined. I know the cost isn't practical but the experience and learning curve will be priceless.