- Messages

- 103

- Reactions

- 17

Hey guys -

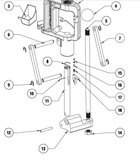

I sat down and loaded a bunch of rounds last week, and when I went to seat the bullets, the cases weren't sized properly (yes, I know, I should have checked before I loaded them with powder - GREAT lesson learned). I fixed those cases (took hours), but as I sat down for another reloading session, it turns out the problem wasn't the in the die as I first thought, but was the pin used to secure the cam at the base of the press handle to the ram. The pin had worked itself out, and was blocked by a stabilizer bar keeping the ram from moving the last 1/4" of the stroke. I used a hammer to get the pin back in place (carefully), but it worked itself back out by the end of the evening (I only re-sized 80 cases of 45, and loaded 25 cases of .308 from sizing to crimp). I don't see any place on the pin for a clip or retainer ring, and the pin is pretty stout - doesn't look like it should move! The press was factory new a year ago.

Any ideas? Is this a common problem with these presses?:huh:

Thanks,

Bobby

I sat down and loaded a bunch of rounds last week, and when I went to seat the bullets, the cases weren't sized properly (yes, I know, I should have checked before I loaded them with powder - GREAT lesson learned). I fixed those cases (took hours), but as I sat down for another reloading session, it turns out the problem wasn't the in the die as I first thought, but was the pin used to secure the cam at the base of the press handle to the ram. The pin had worked itself out, and was blocked by a stabilizer bar keeping the ram from moving the last 1/4" of the stroke. I used a hammer to get the pin back in place (carefully), but it worked itself back out by the end of the evening (I only re-sized 80 cases of 45, and loaded 25 cases of .308 from sizing to crimp). I don't see any place on the pin for a clip or retainer ring, and the pin is pretty stout - doesn't look like it should move! The press was factory new a year ago.

Any ideas? Is this a common problem with these presses?:huh:

Thanks,

Bobby