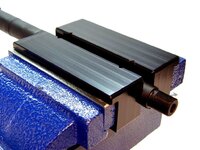

anybody have the know how or can recommend a gunsmith in the Vancouver Portland area that can retorque a 16 inch ar15 barrel back Into the barrel extension? went to take my flash hider off that I've had off before and the barrel started turning. got the barrel nut off and got the extension out. doesn't looks like the index pin is broken just wasn't seated very well.