- Messages

- 171

- Reactions

- 97

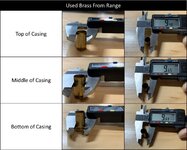

Problem: bottom of casing seems to get shaved off a bit with some offset on one side. When pushing the casing into the die, often it wouldn't seat right, had to give it a gentle guiding push from the front towards the back of the press.

The set up is new to me:

How would adjust or fix this?

The set up is new to me:

- Hornady Single Stage Iron.

- #8 shell holder. I've checked the oring around the silver color shellholder plate is intact and there's a slight pressure when pushing in around the shellholder.

- Hornady decaping die.