- Messages

- 381

- Reactions

- 529

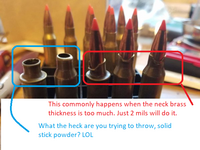

So I recently bought a used lnl ap press from a member on here, and when I started loading 223 a few months back and have had this problem intermittently. If I use any sort of stick powder the powder measure seems to jam and it destroys the mouth of the case. Some throws go effortlessly other are near impossible. Is my powder measure defective? Am I doing something wrong? I found I can relieve the pressure on the case mouth by pushing the arm up. Help me out here guys. Experience or suggestions greatly appreciated! Here's a picture of the outcome....