- Messages

- 128

- Reactions

- 399

I have found lots of guns with buggered up screws because someone used the wrong type of screw driver on them. you should always use a HOLLOW ground screw driver.

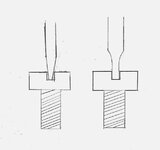

The results of using the wrong screwdriver look like this:

Fortunately, the repair is easy and anyone can do at home with minimal tools

The first step is to "peen" the metal back into shape, you will need a brand new ball peen hammer (or an old one with a freshly ground and polished face). the face of the hammer must be smooth or your results will vary as the dents in the hammer face will affect the surface of the screw head.

Once you have the hammer, find a piece of steel (1/4 or thicker) and drill a hole just slightly larger than the threads of the screw

Wrap the threads of the screw with masking tape and seat it in the hole

next gently "peen" the metal back down, remember to move the hammer around and don't strike it too hard. the object is to push the metal back down close to its original location.

Next take a parallel needle file that is the correct width for the slot and file the slot so that you remove the extra metal.

(sorry I forgot to take a picture of that part)

The next step is polishing: get your self a piece of pine wood (any soft wood will suffice), some sand paper (220 & 600 grits), some WD-40 (or other lightweight cutting oil) and a drill. Wrap the screw threads with tape again and chuck it into the drill motor.

Then lay the sand paper onto the pine board and coat with cutting oil, press firmly on to the paper and spin the screw. You can push hard here as the wood will yield to the pressure and create a depression for the screw head. You will need to move it around as the sand paper will get torn up. Start with the 220 grit and finish with the 600 grit (go even higher for a nicer finish)

The next step is re-finishing the screws. I used cold blue which is fine for small parts as it is next to impossible to hot salts blue tiny parts.....

The results of using the wrong screwdriver look like this:

Fortunately, the repair is easy and anyone can do at home with minimal tools

The first step is to "peen" the metal back into shape, you will need a brand new ball peen hammer (or an old one with a freshly ground and polished face). the face of the hammer must be smooth or your results will vary as the dents in the hammer face will affect the surface of the screw head.

Once you have the hammer, find a piece of steel (1/4 or thicker) and drill a hole just slightly larger than the threads of the screw

Wrap the threads of the screw with masking tape and seat it in the hole

next gently "peen" the metal back down, remember to move the hammer around and don't strike it too hard. the object is to push the metal back down close to its original location.

Next take a parallel needle file that is the correct width for the slot and file the slot so that you remove the extra metal.

(sorry I forgot to take a picture of that part)

The next step is polishing: get your self a piece of pine wood (any soft wood will suffice), some sand paper (220 & 600 grits), some WD-40 (or other lightweight cutting oil) and a drill. Wrap the screw threads with tape again and chuck it into the drill motor.

Then lay the sand paper onto the pine board and coat with cutting oil, press firmly on to the paper and spin the screw. You can push hard here as the wood will yield to the pressure and create a depression for the screw head. You will need to move it around as the sand paper will get torn up. Start with the 220 grit and finish with the 600 grit (go even higher for a nicer finish)

The next step is re-finishing the screws. I used cold blue which is fine for small parts as it is next to impossible to hot salts blue tiny parts.....