Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Any P80 experts out there?

- Thread Starter jeffery2Awae

- Start date

-

- Tags

- p80

- Messages

- 71

- Reactions

- 37

- Thread Starter

- #22

No sir that's installedDid you forget the rear pin that holds the rear rail section to the grip? Also holds the trigger housing in place

Silver Supporter

- Messages

- 9,115

- Reactions

- 16,640

This can happen if the seat spring is installed wrong.

When you buy the serialized frame, does it come 100% populated ?No sir that's installed

Im not an expert but this is my experience.Trigger will reset if I let slide go slowly back into battery or if I rack it quickly but not if I keep my finger with trigger depressed on either method. I think maybe the rails on the lower are too high?

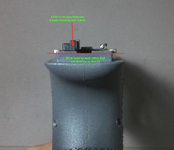

The rail height shouldnt be an issue on a serialized frame (its a problem with the home built ones...) but if they are too high on the RRM then the cruciform might skip over the firing pin sear. To check if your rear rails are too high they should look like this...

It also could be your trigger spring could be installed incorrectly.

The first thing I would check is the sear engagement, it needs to be at least 80% or better (or you can get binary fire....). The orange cover plate is a gunsmithing tool that allows you to view this (although with a good eye, a flashlight and maybe an assistant you might be able to see thru the cracks at an angle...). Your engagement should look like this...

In that pic the cruciform (trigger bar "tab") is almost entirely engaging the firing pin sear. IIRC This is what pushes your trigger forward to reset it when the slide returns home. Since your not getting a reset, my guess is your cruciform is entirely missing the sear. This could also be caused by a bad or improperly installed connector not resetting the cruciform but....

Your first step is to confirm at least 80% sear engagement....?

Reference article: http://web.archive.org/web/20210413....com/post/p80-basic-tips-for-trouble-shooting

Glock gunsmithing cover plate: https://www.midwayusa.com/product/1004275310

- Messages

- 16

- Reactions

- 29

After thinking through some previous builds I'd bet it is your connector angle.

I've had several Glock OEM connectors fail the paper test, they should all be tested when installed.

The instructions here are from Ghost but apply to any Glock connector.

See section 2 step 2 for the test.

https://ghostinc.com/connector-installation-instructions/

I've had several Glock OEM connectors fail the paper test, they should all be tested when installed.

The instructions here are from Ghost but apply to any Glock connector.

See section 2 step 2 for the test.

https://ghostinc.com/connector-installation-instructions/

- Messages

- 221

- Reactions

- 212

I second @interczeptor

I had this issue with a build. Trigger would not reset with live ammo sometimes, would "binary" dry firing and would function properly other times.

The interaction between lower/connector/slide was messed up. Try bending your connector out, far from the housing and function check it.

I had this issue with a build. Trigger would not reset with live ammo sometimes, would "binary" dry firing and would function properly other times.

The interaction between lower/connector/slide was messed up. Try bending your connector out, far from the housing and function check it.

I looked out of curosity... but I am going to strongly suggest you do not insert your connector into the housing in reverse to reset the connector angle...as suggested. You risk compromising the hold tolerances of the connector slot which may lead to long term reliability issues. If you must... a bench vice or similar is your friend.After thinking through some previous builds I'd bet it is your connector angle.

I've had several Glock OEM connectors fail the paper test, they should all be tested when installed.

The instructions here are from Ghost but apply to any Glock connector.

See section 2 step 2 for the test.

https://ghostinc.com/connector-installation-instructions/

It's always best to check the non-invasive stuff and fully diagnose the issue before trying any of the DIY "fixes" you might find online. From my experience, rail alignment/angle/tracking is a common culprit. KISS... double check your reset spring is not installed upside down.. it matters. Is the connector fully seating in the housing? Also rechecking your housing pin hole alignment and housing seating depth.

Checking the sear engagement will let you know if you're on track and really should be done anyway as part of the function testing before attempting any live fire.

Resetting the angle on a connector or any alteration on the cruciform would be a last option. Although.... considering the realtively inexpensive costs, I would first opt for a part swap and reserve any parts found to be wanting for tinkering purposes.

It's not common for OEM parts to fall out of spec or have imprefections/burrs/malformation, but if you are using 3rd party internals, slight defects like that may be more common and are typically very easily correctable. An ever so slight friction point where there shouldn't be can really gum up the works, but takes only moments to correct.

Checking the sear engagement will let you know if you're on track and really should be done anyway as part of the function testing before attempting any live fire.

Resetting the angle on a connector or any alteration on the cruciform would be a last option. Although.... considering the realtively inexpensive costs, I would first opt for a part swap and reserve any parts found to be wanting for tinkering purposes.

It's not common for OEM parts to fall out of spec or have imprefections/burrs/malformation, but if you are using 3rd party internals, slight defects like that may be more common and are typically very easily correctable. An ever so slight friction point where there shouldn't be can really gum up the works, but takes only moments to correct.

- Messages

- 16

- Reactions

- 29

It takes very little pressure and you're only bending the connector a tiny amount at a time. I see no way you could possibly hurt anything but I'm not a Glock armorer so ymmv. That said I have fixed the exact problem OP is having on a personal firearm by doing this so...

Edit: I posted the link to explain the paper test which will verify the connector angle is close. Don't start modifying things until you confirm this is not the case with the paper test AND visually inspecting operation using an inspection plate.

Edit: I posted the link to explain the paper test which will verify the connector angle is close. Don't start modifying things until you confirm this is not the case with the paper test AND visually inspecting operation using an inspection plate.

Last Edited:

- Messages

- 16

- Reactions

- 29

This video shows the procedure, also from Ghost.

I'm not saying that you might not be able to get away with it. What I know is that polymer has more "give" in it than metal does. Anything that may expand the connector slot runs the risk of lightening the hold potential. Your particular connector may require only a hairs adjustment while others may require more. Various aftermarket connectors may have varied tensile strengths. Some housings may be older, or lesser quality, more brittle or even softer due to a variety of condtions/factors. You may trust yourself not to "slip" or apply too much pressure. Others many not... so recommending it to all as standard procedure does not seem wise when other means are available, guaranteed "safe" and have zero potential impact on other interal parts.It takes very little pressure and you're only bending the connector a tiny amount at a time. I see no way you could possibly hurt anything but I'm not a Glock armorer so ymmv. That said I have fixed the exact problem OP is having on a personal firearm by doing this so...

Edit: I posted the link to explain the paper test which will verify the connector angle is close. Don't start modifying things until you confirm this is not the case with the paper test AND visually inspecting operation using an inspection plate.

From experience, I also know that the leading cause of performance issues is when inexperienced folks "tinker"... even slightly can have detrimental and unexpected affects. If I had a dollar for every time I heard, "all I did was lightly polish it" or "all I did was expand the spring a few times to lighten it", etc etc.

When you're addressing the masses with varied degrees of common sense and/or experience it's typically best to offer up the best "foolproof" method. Other than convenience I don't see a practical reason to recommend that method and personally wouldn't instruct anyone to do so.

Just sayin..... Your firearm, your choice.

- Messages

- 71

- Reactions

- 37

- Thread Starter

- #32

Thanks for all the replies! I'll give them a try most likely sometime today! I think maybe I'm having a problem with extra material in the the front of the lower? Feels like maybe the recoil spring is making contact I shall see

- Messages

- 71

- Reactions

- 37

- Thread Starter

- #33

Also I'm noticing when I pull my slide back the trigger goes back as well? Maybe I need to smooth out the safety plunger?

Silver Supporter

- Messages

- 9,115

- Reactions

- 16,640

Wait. What ?Thanks for all the replies! I'll give them a try most likely sometime today! I think maybe I'm having a problem with extra material in the the front of the lower? Feels like maybe the recoil spring is making contact I shall see

I thought that this was a serialized frame ?

Don't these come fully finished and fully populated with all the small parts ?

- Messages

- 221

- Reactions

- 212

They were still milled at the factory/shop that serialized them. Could easily have some extra material due to some error.Wait. What ?

I thought that this was a serialized frame ?

Don't these come fully finished and fully populated with all the small parts ?

- Messages

- 584

- Reactions

- 356

I've gunsmith a few of theses. And advised on some P80 80% (didn't touch just watch the owner do everything and gave my input).

I've replaced and advised on over 50 of theses. The P80 serialized and P80 LP Kits sold for builds, do not use Glock OEM parts, they are "p80" branded.

Replace the trigger bar (trigger bar has the crucifix on it) with an OEM one. 100% of the time it fixed the problem.

ZEV and many other aftermarket trigger companies when they include a trigger bar, usually do some modification of the trigger bar (polishing, reforming, etc) to achieve a different trigger result

I've replaced and advised on over 50 of theses. The P80 serialized and P80 LP Kits sold for builds, do not use Glock OEM parts, they are "p80" branded.

Replace the trigger bar (trigger bar has the crucifix on it) with an OEM one. 100% of the time it fixed the problem.

ZEV and many other aftermarket trigger companies when they include a trigger bar, usually do some modification of the trigger bar (polishing, reforming, etc) to achieve a different trigger result

- Messages

- 584

- Reactions

- 356

https://www.glockstore.com/Glock-Trigger-w-Bar?quantity=1&custcol21=1

EDIT: Posted as an example, you may order from anywhere you'd like. Just make sure it's Factory Glock/Glock OEM

EDIT: Posted as an example, you may order from anywhere you'd like. Just make sure it's Factory Glock/Glock OEM

Last Edited:

- Messages

- 71

- Reactions

- 37

- Thread Starter

- #38

It's serialized but still feels like spring is making contact. What are you a tyrant or something? You work for the dog killers?Wait. What ?

I thought that this was a serialized frame ?

Don't these come fully finished and fully populated with all the small parts ?

It's possible. More likely on the "gen 4" type dual springs, but it can't hurt to check your recoil spring alignment and inspect the the frame channel. It's really no big deal to find tune the channel with a bit of sandpaper and/or just smooth it out with a fine oiled wet/dry paper. You might use a bit of sharpie marker, talc or other to run your slide a few times and diagnose where there may be unwanted contact.It's serialized but still feels like spring is making contact. What are you a tyrant or something? You work for the dog killers?

To note: Ensure the recoil spring plate resting on the lug is square to the guide rod. I've seen those tweaked slightly out of square a few times.

Last Edited:

- Messages

- 71

- Reactions

- 37

- Thread Starter

- #40

Hey guys thanks for all the tips! I HAVE RETURNED WITH GREAT NEWS! I got this SOB running like a faucet! The fix for me was bending the the part of the trigger bar that holds the firing pin, upwards a little bit! Also to cover all bases I polished all the rails. I am beyond happy right now I appreciate each and every one of you that took time out of your day to help me thanks again! CHEERS!

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

Benelli M4 OD Green w/Titanium CarrierComp Tube & Urbino Stock

- Started by clanhanson

- Replies: 0

-

XM177E2 RETRO 5.56 AR-15 CARBINE STOCK, Coated Aluminum Colt Copy.

- Started by eldbillbo

- Replies: 0

-

-

Bushnell RXS-250 Reflex Sight (RXS250) - $124.99 - free shipping over $175

- Started by Richo877

- Replies: 0

-

Federal Champion Training .22LR 36gr Lead HP 325rd Box - $17.32 - Free shipping over $175

- Started by Richo877

- Replies: 0

-

500rd can American Eagle .45 ACP 230gr - $189.99 - Free shipping

- Started by Richo877

- Replies: 0

-

100 rds 7.62x39 with 26 sks stripper clips

- Started by gunsmith007

- Replies: 0

-

Winchester Ranger T-Series .40 S&W 180gr JHP - $24.99 - Free shipping over $175

- Started by Richo877

- Replies: 0

-

CADEX DEFENCE CDX-R7 SPORTER SHORT ACTION RIFLE 6.5 PRC 24" Cadex Barrel in Hybrid TAN/BLACK

- Started by Riflecrafters

- Replies: 0

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale