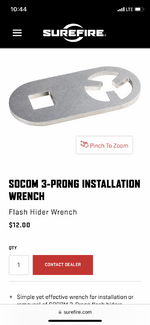

Recently acquired a rifle with a Warcomp (the three-prong one, which evidently has a special tool for install/removal) that I agreed to send back to the original owner. Tried to get it off with my meager selection of tools but didn't want to mess anything up, as I don't have a vice block. Anyway, was wondering if anyone in the Medford/Ashland area has the necessary set-up to help out with this, thanks.

Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Member 34319

- Messages

- 17,146

- Reactions

- 37,067

Crush washer or?

No crush washer means it might have a form of thread locking agent on it.

If it's just a crush washer, put a screwdriver in between the tines and lefty loosy.

If no crush washer, take a lighter to the area in the rear of the comp where the threads should be inside for about 30 seconds to a minute and then take a screwdriver in between the tines and lefty loosy.

No vise block? Position the rifle in way that the grip and most of lower and upper is fully in between your thighs for leverage. Or place rifle in tight, put sturdy, space where the grip will catch if rotated to use as leverage.

Screwdriver between tines shouldn't mar it up too bad, if at all. Then again, if the prior owner wanted it so badly they should have taken it off themselves.

No crush washer means it might have a form of thread locking agent on it.

If it's just a crush washer, put a screwdriver in between the tines and lefty loosy.

If no crush washer, take a lighter to the area in the rear of the comp where the threads should be inside for about 30 seconds to a minute and then take a screwdriver in between the tines and lefty loosy.

No vise block? Position the rifle in way that the grip and most of lower and upper is fully in between your thighs for leverage. Or place rifle in tight, put sturdy, space where the grip will catch if rotated to use as leverage.

Screwdriver between tines shouldn't mar it up too bad, if at all. Then again, if the prior owner wanted it so badly they should have taken it off themselves.

Gold Supporter

- Messages

- 3,742

- Reactions

- 3,032

If it was installed properly, it will have shims and be Rockset'ed, which is removed by putting it in boiling water, heat from a lighter or torch won't loosen it, Rockset is meant to withstand like 2000 degrees. It shouldn't be torqued too tight. it may work to use channel locks or a pipe wrench on the flat area (wide spot) with a piece of leather wrapped around it.

- Messages

- 18,744

- Reactions

- 45,458

DO NOT use a screw driver to loosen, you will most likely end up damaging your MD.If it's just a crush washer, put a screwdriver in between the tines and lefty loosy.

Here is what Forward Controls says about using screw drivers on their MDs, which are closed tine design:

https://www.forwardcontrolsdesign.com/6315KM-12x28_p_191.html

CAUTION!

We will no longer replace muzzle devices damaged from improper installation.

6315KM has wrench flats for torquing it on the barrel. Do not use a screwdriver and insert it into one of its ports to torque it. With 30ft lbs of torque, using a rod or screw driver will cause damage to the muzzle device.

JMW (Joint Muzzle device Wrench) was designed specifically for use on suppressor mounts: https://www.forwardcontrolsdesign.com/jmw-joint-muzzle-device-wrench.html

@RedneckRampage is correct, I would assume Rocksett has been used. I would put in boiling water and let it soak overnight. If that doesn't work then likely some knothead used red Loctite which requires heat to break loose. All that said there is no "special tool" needed beyond a thin wrench, many crescent and open-ended wrenches are too wide to fit the flats. FCD addresses that with his JMW (second link) and standard thin open-end wrench will do the same thing.

Gold Supporter

- Messages

- 3,742

- Reactions

- 3,032

The three prong Warcomps do not have flats, they take a "wrench" that fits inside the tines, that comes with the MD.DO NOT use a screw driver to loosen, you will most likely end up damaging your MD.

Here is what Forward Controls says about using screw drivers on their MDs, which are closed tine design:

https://www.forwardcontrolsdesign.com/6315KM-12x28_p_191.html

CAUTION!

We will no longer replace muzzle devices damaged from improper installation.

6315KM has wrench flats for torquing it on the barrel. Do not use a screwdriver and insert it into one of its ports to torque it. With 30ft lbs of torque, using a rod or screw driver will cause damage to the muzzle device.

JMW (Joint Muzzle device Wrench) was designed specifically for use on suppressor mounts: https://www.forwardcontrolsdesign.com/jmw-joint-muzzle-device-wrench.html

@RedneckRampage is correct, I would assume Rocksett has been used. I would put in boiling water and let it soak overnight. If that doesn't work then likely some knothead used red Loctite which requires heat to break loose. All that said there is no "special tool" needed beyond a thin wrench, many crescent and open-ended wrenches are too wide to fit the flats. FCD addresses that with his JMW (second link) and standard thin open-end wrench will do the same thing.

- Messages

- 18,744

- Reactions

- 45,458

Then they must have changed, mine does have narrow flats and did not come with a tool...The three prong Warcomps do not have flats, they take a "wrench" that fits inside the tines, that comes with the MD.

View attachment 1433309

or the OP has the non-suppressor flash hider version not an actual Warcomp.

Last Edited:

Gold Supporter

- Messages

- 3,742

- Reactions

- 3,032

Crazy, mine (or any of the few I have had) doesn't have flats.Then they must have changed, mine does have narrow flats and did not come with a tool...

View attachment 1433311

or the OP has the non-suppressor flash hider version not an actual Warcomp.

Member 34319

- Messages

- 17,146

- Reactions

- 37,067

Jerry Rigging ain't easy!DO NOT use a screw driver to loosen, you will most likely end up damaging your MD.

Here is what Forward Controls says about using screw drivers on their MDs, which are closed tine design:

https://www.forwardcontrolsdesign.com/6315KM-12x28_p_191.html

CAUTION!

We will no longer replace muzzle devices damaged from improper installation.

6315KM has wrench flats for torquing it on the barrel. Do not use a screwdriver and insert it into one of its ports to torque it. With 30ft lbs of torque, using a rod or screw driver will cause damage to the muzzle device.

JMW (Joint Muzzle device Wrench) was designed specifically for use on suppressor mounts: https://www.forwardcontrolsdesign.com/jmw-joint-muzzle-device-wrench.html

@RedneckRampage is correct, I would assume Rocksett has been used. I would put in boiling water and let it soak overnight. If that doesn't work then likely some knothead used red Loctite which requires heat to break loose. All that said there is no "special tool" needed beyond a thin wrench, many crescent and open-ended wrenches are too wide to fit the flats. FCD addresses that with his JMW (second link) and standard thin open-end wrench will do the same thing.

Sounds like a great way to add a sale for a proper wrench. Marketing!

- Thread Starter

- #9

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

Benelli M4 OD Green w/Titanium CarrierComp Tube & Urbino Stock

- Started by clanhanson

- Replies: 0

-

XM177E2 RETRO 5.56 AR-15 CARBINE STOCK, Coated Aluminum Colt Copy.

- Started by eldbillbo

- Replies: 0

-

-

Bushnell RXS-250 Reflex Sight (RXS250) - $124.99 - free shipping over $175

- Started by Richo877

- Replies: 0

-

Federal Champion Training .22LR 36gr Lead HP 325rd Box - $17.32 - Free shipping over $175

- Started by Richo877

- Replies: 0

-

500rd can American Eagle .45 ACP 230gr - $189.99 - Free shipping

- Started by Richo877

- Replies: 0

-

100 rds 7.62x39 with 26 sks stripper clips

- Started by gunsmith007

- Replies: 0

-

Winchester Ranger T-Series .40 S&W 180gr JHP - $24.99 - Free shipping over $175

- Started by Richo877

- Replies: 0

-

CADEX DEFENCE CDX-R7 SPORTER SHORT ACTION RIFLE 6.5 PRC 24" Cadex Barrel in Hybrid TAN/BLACK

- Started by Riflecrafters

- Replies: 0

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale