Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Gold Supporter

Bronze Supporter

- Messages

- 24,915

- Reactions

- 59,292

Try a Lee die, they make the best stuff in the world.

Lol, you might have to customize it with JB Weld or the like and or contact Forster to see if they have stems with a more suitable profile.

Lol, you might have to customize it with JB Weld or the like and or contact Forster to see if they have stems with a more suitable profile.

- Thread Starter

- #3

$34 + some of my unprimed cases and bullets for a custom fit seating stem.or contact Forster to see if they have stems with a more suitable profile.

I guess there are many bullet profiles out there but.... kinda lame a common Nosler Partition isnt in their generic design..

I guess now, as along as it doesn't affect accuracy?

Custom Machining Services

Custom Machining to Your Specifications Allow 3-4 weeks delivery for Collets, Neck Reamers, Outside Neck Turner Pilots; 2 weeks for Case Trimmer pilots. Case Trimmer...

Bronze Supporter

- Messages

- 37,260

- Reactions

- 128,559

I can see those rings causing turbulence and thus affecting projectile trajectory.

- Thread Starter

- #7

Well this is discouraging to read.

Ill have to contact Forster.... So frustrating to "upgrade" to this seating die only to waste my time loading with it.

Ill get velocity data from these today for my load development so not all is lost but who knows what I will get with group size.

I shoulda bought the RCBS match grade seater, it had a micrometer too. But I liked the way Forsters holds the entire case for concentricity.

Ill have to contact Forster.... So frustrating to "upgrade" to this seating die only to waste my time loading with it.

Ill get velocity data from these today for my load development so not all is lost but who knows what I will get with group size.

I shoulda bought the RCBS match grade seater, it had a micrometer too. But I liked the way Forsters holds the entire case for concentricity.

- Messages

- 14,911

- Reactions

- 27,440

I agree. Bullets should typically seat with little to no resistance and by the look of those rings it appears you are really putting some serious pressure on them.Those marks are pretty severe. Seems something else is going on. Is the load heavily compressed?

And item # 2 - are those bullets fully seated in the cases in the pic ?

- Thread Starter

- #9

Bullets are fully seated, note im not using the cannelures or crimping for my loads. I didnt notice any excessive pressure seating them compared to my other seating die.I agree. Bullets should typically seat with little to no resistance and by the look of those rings it appears you are really putting some serious pressure on them.

And item # 2 - are those bullets fully seated in the cases in the pic ?

Are these boat tail bullets? Isn't that all everyone uses anymore? Except some of us shooting antiques with long leads maybe. I notice more resistance initially to seat a flat base bullet. But it doesn't feel like it should be enough to leave a ring like that. Or maybe a little more with the deburring tool on the inside?Bullets are fully seated, note im not using the cannelures or crimping for my loads. I didnt notice any excessive pressure seating them compared to my other seating die.

Staff Member

Silver Lifetime

Bronze Lifetime

- Messages

- 7,053

- Reactions

- 8,761

Take the insert out and taper it with a drill bit in a press, I had to do this for the FTX hornady's in 357. shouldn't take much to bust the edge off to better fit the curve. I would also open up the neck just a tad to reduce the tension, it may just be too much initially when inserting the bullet. I've had to modify a few dies when issues like this come up, even had to add a couple gas checks as spacers to get enough adjustment for seating 7.62x39 SST's.

I use the Redding Competition Seater for several cartridges and it works fine (no heavy marks). (EDIT: just saw you're using Forster. Should still be good. ). I would double-check that you got the standard seating stem, not the VLD stem. I'd also explore if there are any aspects of your neck sizing that might be increasing pressure when you seat. Do you know your neck tension? Are the inside of the neck mouths chamfered?

- Thread Starter

- #13

I dont know my neck tension, or even how to measure that?I use the Redding Competition Seater for several cartridges and it works fine (no heavy marks). (EDIT: just saw you're using Forster. Should still be good. ). I would double-check that you got the standard seating stem, not the VLD stem. I'd also explore if there are any aspects of your neck sizing that might be increasing pressure when you seat. Do you know your neck tension? Are the inside of the neck mouths chamfered?

These are brand new cases, never fired. Came ready to load, even the mouth are chamfered nicely. I did measure them and the all weighed the same and same length... Everythings consistent with them.

- Messages

- 14,911

- Reactions

- 27,440

Did the package/box the cases came in specifically indicate they were 'ready to load' ?These are brand new cases, never fired. Came ready to load

Typically this is not the case and they need to be sized & prepped prior to loading.

Last Edited:

Quick way: if you have some cases that haven't been loaded yet, measure the outside diameter of the neck. Then do the same for some loaded cases. The difference is the neck tension.I dont know my neck tension, or even how to measure that?

Target shooters often want 0.001-0.002. A common range for hunting loads is about 0.003-0.005. Much more than 0.005 will increase seating pressure quickly.

Staff Member

Silver Lifetime

Bronze Lifetime

- Messages

- 7,053

- Reactions

- 8,761

Did the package/box the cases came in specifically indicate they were 'ready to load' ?

Typically this is not the case and they have to sized & prepped prior to loading.

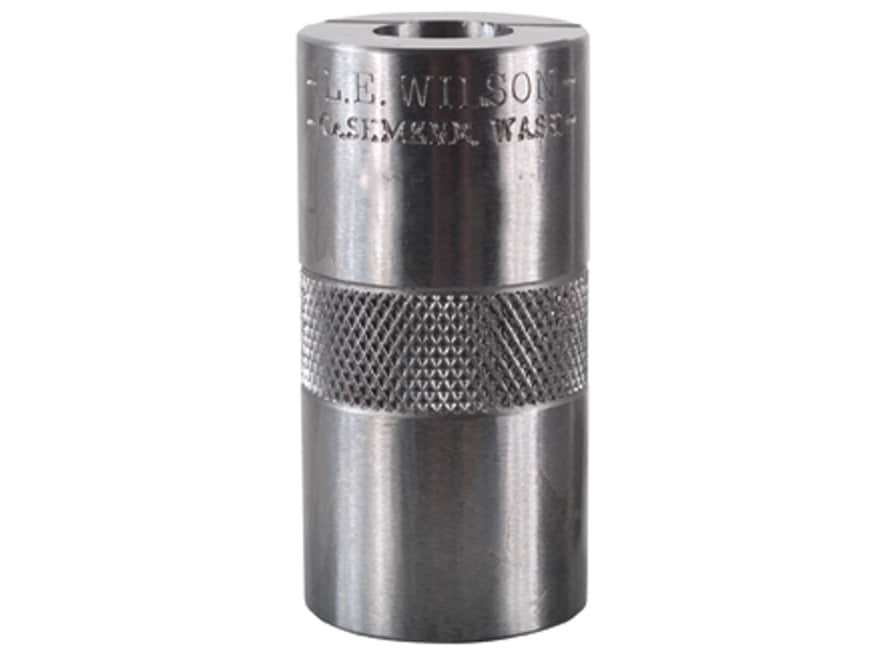

Big YEP, this is why a certain tool comes in handy........even after loading. Definitely lets ya know if you're doing it wrong and is almost a must with semi/full auto.

L.E. Wilson Case Length Headspace Ga 22-250 Remington

L.E. Wilson has been making precision reloading tools for over 80 years. The Case Length Headspace Gauge allows reloaders to measure case length from...

- Thread Starter

- #17

Noslers website video i think said so, they came chamfered properly I measured their case headspace and it was in spec, the neck inside diameter would not accept a bullet by hand.... So I assumed all was good. ...there was a case that had a dent in it that I rejected, I ran that thru the size die to measure and it actually pushed the shoulder back even farther from my chamber headspace..... So I decided I didnt need to resize these cases....Did the package/box the cases came in specifically indicate they were 'ready to load' ?

Typically this is not the case and they have to sized & prepped prior to loading.

Seating pressure was the same as my other seating die.... I didnt suspect any need to resize them.

- Messages

- 848

- Reactions

- 2,248

It might help to list some of your particulars (caliber/cartridge, bullet spec, COAL, die model, etc.). Maybe someone is running and loading something similar and could replicate (or not) your issue.

Staff Member

Silver Lifetime

Bronze Lifetime

- Messages

- 7,053

- Reactions

- 8,761

read the thread...........25-06, nosler partition, etc. etc.It might help to list some of your particulars (caliber/cartridge, bullet spec, COAL, die model, etc.). Maybe someone is running and loading something similar and could replicate (or not) your issue.

Reloading take 2

new to reloading I tried to get into it earlier this year but manufacturing shortages put my load development on hold as my small sample of powder I scrounged up was being used. I signed up for notifications on various websites and moved on to other things.... few months went by, and then...

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

Icarus Sig P320 ACE Grip Module with safety cutout

- Started by icampnw

- Replies: 0

-

Icarus ACE M17/18 Sig P320 Grip Module w/ safety cutout

- Started by icampnw

- Replies: 0

-

WTT: Winchester 40 S&W, 10mm Auto Bullets 175 Grain Silvertip Hollow Points

- Started by Caveman Jim

- Replies: 0

-

-

-

-

-

-

Firearms Unknown Upper - AR15 16" Fixed rifle stock Magpul

- Started by JadonD123

- Replies: 0

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale