- Messages

- 713

- Reactions

- 1,900

PM me anytime. I have put together a lot. It never bothers me to help others.Lebanon.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

PM me anytime. I have put together a lot. It never bothers me to help others.Lebanon.

Two Hundred plus AR15 builds and guess what? I still lose stuff! Gone With The Wind! Amazing hang times! Lost forever in the deep shag carpet which should never have been laid in the Man Cave! Yikes Indeed!

I learned long ago those are call "Jesus springs". They launch for parts unkown and you will say, Jesus!, where did it go?The springs I hate are the ones that are so small that they are hard to find if they fly out.

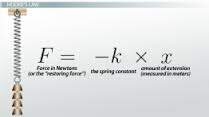

I think your beef with springs is not so much with the spring itself, but with Hooke's Law & the Spring Constant.

View attachment 340295

Hooke's law states that the force needed to compress or extend a spring is directly proportional to the distance you stretch it. As an equation, Hooke's law can be represented as F = kx, where F is the force we apply, k is the spring constant, and x is the extension of the material (typically in meters)

And a simple fix to this is as follows:

Tap it with a 4-40 plug tap, trim .125 off the spring, purchase a 4-40 set screw from any hardware store, install set screw.

View attachment 340280

View attachment 340281

View attachment 340282

View attachment 340283

View attachment 340284

View attachment 340285

View attachment 340286

View attachment 340287

View attachment 340288

View attachment 340289

Should make an endplate that caters to easy access to a screw. Something like an Allen head or something common. new product on your hands.And a simple fix to this is as follows:

Tap it with a 4-40 plug tap, trim .125 off the spring, purchase a 4-40 set screw from any hardware store, install set screw.

View attachment 340280

View attachment 340281

View attachment 340282

View attachment 340283

View attachment 340284

View attachment 340285

View attachment 340286

View attachment 340287

View attachment 340288

View attachment 340289