- Messages

- 1,413

- Reactions

- 2,561

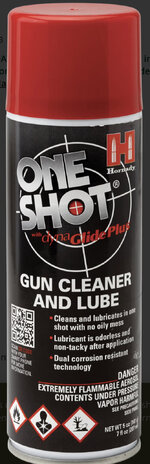

I use to use Hornady OneShot then I switched over to home made spray lube.

I think the home made lube works better then OneShot lube and is a lilot cheaper to make.

I bought liquid lanolin on Amazon and the red bottle of dry gas from Walmart.

Mix it ten to one and you are good to go.

I put the brass in the plastic tray from McDonald's big breakfast comes in. Give it a couple of squirts, roll the brass around and give it a few more shot of lube. I wait about five minutes for the achohol to evaporate before I start to resize the brass.

I think the home made lube works better then OneShot lube and is a lilot cheaper to make.

I bought liquid lanolin on Amazon and the red bottle of dry gas from Walmart.

Mix it ten to one and you are good to go.

I put the brass in the plastic tray from McDonald's big breakfast comes in. Give it a couple of squirts, roll the brass around and give it a few more shot of lube. I wait about five minutes for the achohol to evaporate before I start to resize the brass.