Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

- Messages

- 57

- Reactions

- 27

Initially I had similar issues as fmiller on my Hornady LNL progressive press.

Initially I had similar issues as fmiller on my Hornady LNL progressive press.Once the primer not seated properly and dragged on the main plate, it caused the index out of sync. This is what I did.

1) Examined the pawls. Saw that it was worn out due to my improper dragging/forcing the handle when the primer was not seated properly. So I bought new one.

2) Examined the drive hub. The little key on the drive hub was half broken. This is probably also due to the forcing as above. I also bought new one.

3) Examined the slide assembly. Its edge was rough. I used the 800 grit sand paper and slowly sand down all the edges until it was all smooth. Note that I sanded it down very carefully not to remove much material but to only to make it smooth around the edges only. I also sanded down the hole on the slide assembly where primer would be fed through so that it was also smooth out.

With the new pawls, new drive hub, sanded slide assembly, I put them all back and re-index the plate. Things went smooth from that point on. Thousands of pistol and rifle rounds going smooth so far. No more hiccup

Hope this help.

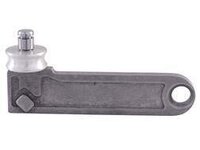

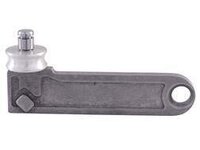

BTW, here's the picture I got from internet to show what the drive-hub and slide assembly look like.

- Messages

- 57

- Reactions

- 27

Oh, and I forgot to mentioned one thing. I pushed on handle twice to firmly seat the primer. One push is not enough to make it seat flush into the case.

And yeah, I too, hate that the primer seater plug make a small dent on the press. I'd imagine the dent only get deeper over time. Need to get myself a small thin hard steel plate to place under the seater plug one of these days.

And yeah, I too, hate that the primer seater plug make a small dent on the press. I'd imagine the dent only get deeper over time. Need to get myself a small thin hard steel plate to place under the seater plug one of these days.

Oh, and I forgot to mentioned one thing. I pushed on handle twice to firmly seat the primer. One push is not enough to make it seat flush into the case.

And yeah, I too, hate that the primer seater plug make a small dent on the press. I'd imagine the dent only get deeper over time. Need to get myself a small thin hard steel plate to place under the seater plug one of these days.

I use a single edge razor blade over the dent to seat a primer deeper, and add another razor blade if the primer doesn't seat deep enough.

For Tula/Wolf primers I always use 2 razor blades and push the handle with crushing force, when Tula was all I could get.

All this on a green machine but would work the same on a red one

just sayin'

- Messages

- 11,840

- Reactions

- 11,103

Never liked mine. Sold it easily and bought a Dillon 650.

Twice the press as the Hornady. Way easier in every aspect .

Wish I wouldn't have sold it but wasn't into reloading as much as some.

If I get another progressive it will be a blue 650

Twice the press as the Hornady. Way easier in every aspect .

Wish I wouldn't have sold it but wasn't into reloading as much as some.

If I get another progressive it will be a blue 650

Bronze Lifetime

- Messages

- 11,376

- Reactions

- 26,083

I learned on a Lee Loadmaster, where you must pay attention to adjustments, cleanliness and tension. The LnL is a walk in the park by comparison, and my loadmaster worked great for me. Gave that away, and bought the LnL.

Bought the LnL because a 650 was beyond my budget, and I'd watched a 'gunsmith' struggle with his 550.

Cleanliness is key.

I'll do a full cycle of dry runs, completely adjust the powder measure, and then crank out ammo.

Only serious problem I ever had was snapping the drive hub when I forced the ram down with a 308 Win case stuck in the sizer. Hornady replaced it free, had it in 2 days. Every other error would be indicated by the 2nd part of my user name: id10t.

Good luck.

Bought the LnL because a 650 was beyond my budget, and I'd watched a 'gunsmith' struggle with his 550.

Cleanliness is key.

I'll do a full cycle of dry runs, completely adjust the powder measure, and then crank out ammo.

Only serious problem I ever had was snapping the drive hub when I forced the ram down with a 308 Win case stuck in the sizer. Hornady replaced it free, had it in 2 days. Every other error would be indicated by the 2nd part of my user name: id10t.

Good luck.

- Messages

- 454

- Reactions

- 381

I learned on a Lee Loadmaster, where you must pay attention to adjustments, cleanliness and tension. The LnL is a walk in the park by comparison, and my loadmaster worked great for me. Gave that away, and bought the LnL.

Bought the LnL because a 650 was beyond my budget, and I'd watched a 'gunsmith' struggle with his 550.

Cleanliness is key.

I'll do a full cycle of dry runs, completely adjust the powder measure, and then crank out ammo.

Only serious problem I ever had was snapping the drive hub when I forced the ram down with a 308 Win case stuck in the sizer. Hornady replaced it free, had it in 2 days. Every other error would be indicated by the 2nd part of my user name: id10t.

Good luck.

I am quite surprised that someone had issues with a 550, its about as basic as a single stage press when it comes to progressive or semi-progressive presses... on a side note.. not sure if I would bring work to a gunsmith having issues reloading... doesnt give me the warm fuzzies.

- Messages

- 1,312

- Reactions

- 3,198

So tell me if this is a fair assessment of the various progressive reloading platforms (geez.. I get the Willies just typing the word "progressive" after the recent election)

RCBS and Lee.... entry level machine and expect to have issues.

Hornady - step up in reliability, pay a few more buck, but still expect to spend time tweaking the setup.

Dillon - pretty much foolproof... runs pretty much without problems... Downside is you have to sell a child or a kidney to buy one and the entry level SDB is limited to handgun rounds and proprietary dies.

Does that about sum it up ?

RCBS and Lee.... entry level machine and expect to have issues.

Hornady - step up in reliability, pay a few more buck, but still expect to spend time tweaking the setup.

Dillon - pretty much foolproof... runs pretty much without problems... Downside is you have to sell a child or a kidney to buy one and the entry level SDB is limited to handgun rounds and proprietary dies.

Does that about sum it up ?

- Messages

- 454

- Reactions

- 381

How i perceive progressive presses.. This does come from many hours on forums, and I follow a few large facebook grounds for reloading along with a few dillon reloading groups.

Lee - very cheap, but expect parts to break randomly and without warning, also expect to tinker to make it flow

RCBS - stick with a single stage as their progressive is over-priced, RCBS

RCBS Prochucker 5 - Does not include case feeder (610$)

Hornady - AP is 100$ less than dillon 550 but basicly equal, Ammoplant is 1100 and basicly equal for Dillon 650, but will require tinkering and modifications to make it run. Saving grace.. caliber changes are roughly 100$ cheaper per caliber change compared to Dillon.

Hornady AP (405$)

Hornady Ammo Plant (1079$)

Dillon - 550 is reasonably priced 460 for base press, 760 for fully priced out, 650 is 1000 - 1200, Dillons are not without fault. But if you set them up correctly, (dillon provides a DVD that is very in depth of how to set it up correctly) They will run for quite some time.. I have seen posts of Dillon 650's with 500k loaded rounds, and 1050's with over a million before any major work needed to be done, for the 650 Dillon will re-work the whole press for something like 65$.. and it is a lifetime warranty that doesnt matter who the owner is.. if you have it in your hands.. you have a lifetime warranty.

Dillon 550 - No Case Feeder (440$)

Dillon 650 - No Case Feeder (566$)

One thing to note.. Those prices for the dillons come with dies, were as the RCBS and Hornady units you have to buy a set of dies along with the machine.

Lee - very cheap, but expect parts to break randomly and without warning, also expect to tinker to make it flow

RCBS - stick with a single stage as their progressive is over-priced, RCBS

RCBS Prochucker 5 - Does not include case feeder (610$)

Hornady - AP is 100$ less than dillon 550 but basicly equal, Ammoplant is 1100 and basicly equal for Dillon 650, but will require tinkering and modifications to make it run. Saving grace.. caliber changes are roughly 100$ cheaper per caliber change compared to Dillon.

Hornady AP (405$)

Hornady Ammo Plant (1079$)

Dillon - 550 is reasonably priced 460 for base press, 760 for fully priced out, 650 is 1000 - 1200, Dillons are not without fault. But if you set them up correctly, (dillon provides a DVD that is very in depth of how to set it up correctly) They will run for quite some time.. I have seen posts of Dillon 650's with 500k loaded rounds, and 1050's with over a million before any major work needed to be done, for the 650 Dillon will re-work the whole press for something like 65$.. and it is a lifetime warranty that doesnt matter who the owner is.. if you have it in your hands.. you have a lifetime warranty.

Dillon 550 - No Case Feeder (440$)

Dillon 650 - No Case Feeder (566$)

One thing to note.. Those prices for the dillons come with dies, were as the RCBS and Hornady units you have to buy a set of dies along with the machine.

Bronze Lifetime

- Messages

- 11,376

- Reactions

- 26,083

I am quite surprised that someone had issues with a 550, its about as basic as a single stage press when it comes to progressive or semi-progressive presses... on a side note.. not sure if I would bring work to a gunsmith having issues reloading... doesnt give me the warm fuzzies.

That's why gunsmith was in quotes, aka supposed gunsmith, but my observation led me to the same conclusion.

So tell me if this is a fair assessment of the various progressive reloading platforms (geez.. I get the Willies just typing the word "progressive" after the recent election)

RCBS and Lee.... entry level machine and expect to have issues.

Hornady - step up in reliability, pay a few more buck, but still expect to spend time tweaking the setup.

Dillon - pretty much foolproof... runs pretty much without problems... Downside is you have to sell a child or a kidney to buy one and the entry level SDB is limited to handgun rounds and proprietary dies.

Does that about sum it up ?

um, yea...

It seems (to me) the common problem with all progressives that most whine about (not me) is priming problems, mostly related to dirt/crud generated from de-priming and powder spillage.

This leads to "fixes" or work arounds like priming separately, defeating what a progressive is.

The powder spillage problem has been traced to "snappy indexing" and can be remedied with a weaker spring and nylon detent ball, on a Lee, Hornady, RCBS, and other presses.

I've done this spring/ball "fix", even to a press I haven't used yet.

the ball:

3/8" Polypropylene Ball Grade 2 Solid Plastic Sphere (25) J32008 | eBay

Personally, I'm leaning towards de-priming (but not resizing), cleaning/tumbling to get rid of the primer pocket crud, and going to the progressive for priming/loading.

But that's just me,

Gold Supporter

Bronze Supporter

- Messages

- 24,994

- Reactions

- 59,542

Yea, that's the thing.. most "progressive" loaders deprime, then tumble, then.... follow with tumble. Might as well have a negative 2 stage press.um, yea...

It seems (to me) the common problem with all progressives that most whine about (not me) is priming problems, mostly related to dirt/crud generated from de-priming and powder spillage.

This leads to "fixes" or work arounds like priming separately, defeating what a progressive is.

The powder spillage problem has been traced to "snappy indexing" and can be remedied with a weaker spring and nylon detent ball, on a Lee, Hornady, RCBS, and other presses.

I've done this spring/ball "fix", even to a press I haven't used yet.

the ball:

3/8" Polypropylene Ball Grade 2 Solid Plastic Sphere (25) J32008 | eBay

Personally, I'm leaning towards de-priming (but not resizing), cleaning/tumbling to get rid of the primer pocket crud, and going to the progressive for priming/loading.

But that's just me,

I wash and dry my brass and the run it through my auto-turret.

- Messages

- 454

- Reactions

- 381

I tumble in stainless media, and then load directly through in my dillon 550. Even after a thousand rounds or so its not bad, every now and then i wipe off the primer cup or give the shell plate a quick blow with some can'd air. For my rifle rounds I deprime, resize, trim and then tumble and chamfer and debur and then I run through the single stage or dillon and prime and then powder and everything else.

If you run a dedicated head to deprime, you can move quite a bit of brass through an ammoplant or 650 and then tumble it and get it really shiney... a number of small commercial loaders will tumble the brass, then run it through a dillon 1050 to deprime, size, swage, trim and then they will run it through a second machine to prime, check primer, powder drop, powder check, bullet drop, seat, bullet check.

If you run a dedicated head to deprime, you can move quite a bit of brass through an ammoplant or 650 and then tumble it and get it really shiney... a number of small commercial loaders will tumble the brass, then run it through a dillon 1050 to deprime, size, swage, trim and then they will run it through a second machine to prime, check primer, powder drop, powder check, bullet drop, seat, bullet check.

Yea, that's the thing.. most "progressive" loaders deprime, then tumble, then.... follow with tumble. Might as well have a negative 2 stage press.

I wash and dry my brass and the run it through my auto-turret.

yea, I don't know why I'm getting anal about primer pocket crud now, I have not de-primed 1st before, and haven't had problems.

I just found a slick/fast way to de-prime and want to try it at least once.

I bought the stuff (fender washers) to make the fixture but it's been near 0 degrees here lately...to cold for shed time

- Messages

- 78

- Reactions

- 35

I agree. This is what I do on mine, and it helps.I have deprimed batches off 9mm to help with this, in other words deprime prior to cleaning, and it helped out a ton. Even using stainless steel media and a solution with water. The primer pocket and primer are still fairly dirty during the depriming. I think a lot of the trouble is in that fact.

- Messages

- 78

- Reactions

- 35

This is what I do with mine. Got an indestructible RCBS bench primer. It uses the same primer pickup tube system, but is real fast. I got one of those Frankford Arsenal primer gun/loaders, as picking with those things pushes my limits button. I upgraded my press handle to the inline fabrication roller handle, and abandoned the PTX. PTX jars too much. I use the Lee expander. Now life is good again.Also, I think I'm going to give priming off press a try. It seems silly, but in the end it may ultimately save me time and frustration.

Gold Supporter

- Messages

- 69

- Reactions

- 21

I had a lot of the same problems with the lnl but I watched that guys videos a while back and never a problem since. I've loaded thousands of rounds now. I've loaded pistol to rifle..

Gold Supporter

Bronze Supporter

- Messages

- 24,994

- Reactions

- 59,542

I think depriming, then cleaning, then loading defeats the purpose of a progressive press.. you've already done more work to deprime and then clean than it takes to load cleaned brass.

- Messages

- 1,312

- Reactions

- 3,198

Yea, that's the thing.. most "progressive" loaders deprime, then tumble, then.... follow with tumble. Might as well have a negative 2 stage press.

I wash and dry my brass and the run it through my auto-turret.

See, this is what I am struggling with as well... I am seriously considering a progressive press, but unless you are loading clean unfired brass, how do you treat the brass before reloading? Decap, then tumble, then resize and reload? Or Decap/resize on the press, then tumble, then reload? But you need to have reasonably clean cases before you run through the resizing die or risk scarring the die.... in either case it doesn't seem like the nice, smooth, loaded round with every pull of the handle in the videos.

Gold Supporter

Bronze Supporter

- Messages

- 24,994

- Reactions

- 59,542

I clean my brass in a bucket (hot soapy water with some lemi-shine) and rinse well with a colander. Dry then load it. I use a humble auto-indexing Lee turret press.See, this is what I am struggling with as well... I am seriously considering a progressive press, but unless you are loading clean unfired brass, how do you treat the brass before reloading? Decap, then tumble, then resize and reload? Or Decap/resize on the press, then tumble, then reload? But you need to have reasonably clean cases before you run through the resizing die or risk scarring the die.... in either case it doesn't seem like the nice, smooth, loaded round with every pull of the handle in the videos.

Oh and edit in case some didn't quite catch it.. I don't clean my primer pockets in any way shape or form.. save for just washing the brass as above, complete with spent primers in place.

Last Edited:

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

WTS - 50 cal muzzleloader bullets, powder, primers

- Started by pnwair

- Replies: 0

-

Glock 42 .380, 100 rds thru it, including 2 boxes ammo

- Started by lhgunntravel

- Replies: 3

-

-

-

3 Piece Radio Flyer Set; Wagon, big wheels and trike.

- Started by SuperBreed

- Replies: 1

-

3 Piece Radio Flyer Set; Wagon, big wheels and trike.

- Started by SuperBreed

- Replies: 0

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale