- Messages

- 4,996

- Reactions

- 2,279

I posted this on another forum and have had a couple requests to post it here due to people having trouble viewing it there. I thought I posted it here too but I guess I did not since I cannot find it anywhere. I guess my memory is playing tricks on me or my search function is screwy. If it turns out it is already here we can always delete it.

It will seem a little odd since there is a different post for different stages. Even though the project is already finished it will read as if I am posting progress reports as I go. That is kind of necessary to maintain all the info so please bear with me. I am also not editing the content so there will be a few cases where I use an incorrect term or two or where I mislabel a part. The thread really does answer a lot of the questions I get asked each week by board members regarding gun refinishing so it is a pretty good resource.

The progress reports will begin in the next post.

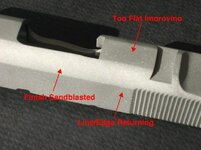

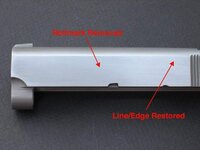

The tools used throughout the project are wet dry sandpaper (100, 300, and 600 grit), a vise, and a $9 siphon feed sandblaster I picked up at Home Depot.

It will seem a little odd since there is a different post for different stages. Even though the project is already finished it will read as if I am posting progress reports as I go. That is kind of necessary to maintain all the info so please bear with me. I am also not editing the content so there will be a few cases where I use an incorrect term or two or where I mislabel a part. The thread really does answer a lot of the questions I get asked each week by board members regarding gun refinishing so it is a pretty good resource.

The progress reports will begin in the next post.

The tools used throughout the project are wet dry sandpaper (100, 300, and 600 grit), a vise, and a $9 siphon feed sandblaster I picked up at Home Depot.