That's a BAD trip Maaan! Gnom'sayin'?Potland strikes again.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

That's a BAD trip Maaan! Gnom'sayin'?Potland strikes again.

Maybe not directly better than factory but certainly more choices and combinations. You can hand tailor your ammo to your preferences. Kinda like the difference between BBQing a burger on your grill in the back yard vs one from In-N-Out burger.Personally, I can not say that I make better than factory ammo. Maaa-bee, if I shot a lot more? And chrono'd everything, with every caliber. And kept meticulous notes of carefully worked up loads....? My brain doesn't work that way though. The boost to my psyche from the process of the reloading game is my drug. Seeing a great-for-me 3 shot group is the HEAD rush.

A lot healthier than cocaine too!

Sure you do!Personally, I can not say that I make better than factory ammo. Maaa-be

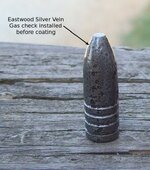

The old rule about keeping cast lead bullets under a thousand fps is something of a myth. There may be some truth in it for store bought, nominally sized bullets using crayon wax for lube, but if you make your own and get your alloy, diameter, and lube right, that speed limit does not apply at all.I am just getting into shooting lead bullets out of a rifle. I have shot a lot out of pistols. The magic number for lead out of a handgun was to keep it under 1000fps. Prevents or reduces leading. Now the rifle has gas checked bullets .002 diameter over the bore. I am not quite sure how to shoot these lead bullets. Any guidance would be appreciated. Can I use lead bullets for fire forming cases?

I remember reading about "plain base gas checks" somewhere, similar to what you describe- thin, soft checks that crimp onto plain base cast bullets. I never used any, but it seemed like those who did liked them.I've been thinking, beer can aluminum is pretty soft. Can't you get one of those circular punches for leather work in a suitable size and stamp them out with that? Then put the disk between the bullet base and the punch and push. Might work.

The way my brain works is, if I get a poor group it could be the ammo or me. When I get a good group, it could be the ammo or me. Though I can tell, sometimes, if I flinched or jerked the trigger.Sure you do!

I've never owned a Chrono and only used one once in my life.

Its all about accuracy for me.

@JRuby ... ThisThe old rule about keeping cast lead bullets under a thousand fps is something of a myth. There may be some truth in it for store bought, nominally sized bullets using crayon wax for lube, but if you make your own and get your alloy, diameter, and lube right, that speed limit does not apply at all.

I have a 30-30 load that uses powder coated, gas checked cast bullets at 2400 fps, that shoots just as well as jacketed, without a trace of leading.

Alox is a generally liquid lube that is applied with a tumble lubed projectile. Usually used on a pistol/revolver caliber... @CLT65 / @Certaindeaf check me here I never used it on rifle stuff?I am new to shooting lead in rifles. Can I simply load lead bullets like I would a copper bullet? What is Alox?

Thank you for the information. Like I indicated this all news to me.Alox is a generally liquid lube that is applied with a tumble lubed projectile. Usually used on a pistol/revolver caliber... @CLT65 / @Certaindeaf check me here I never used it on rifle stuff?

It's kinda smokey when fired and I don't like the odor. I've only used it in lower power revolver and .45acp before. Kinda has an irritating sweet creosote kind of smell. It's sticky and gets on everything and migrates.

I did some rifle with a harder beeswax/parafin/alox lube that worked but it smoked like black powder.

Do you have the cast bullet handbook? Also there is a massive treatise on the subject by Glenn Fryxell online that is quite useful, especially if you want to use traditional lubes. I can look it up and send you the link if you wish.Thank you for the information. Like I indicated this all news to me.

Goodness right up on 3000fps...thanks for throwing that post and pics up. I don't think we've seen the end of potential for PC bullets in all appliations yet. I'm way behind on rifle stuff. It sure works well in magnums and carbines. I've been up to ~ 2000fps in various calibers with plain and bevel base (no gas check) and they have done quite well.@ JRuby The Lyman Cast Bullet handbook #4 is an excellent reference to have if you want to shoot cast bullets in both handguns and rifles, beside Lyman the manual has load for molds made by RCBS, SAECO and Lee. You can download a free PDF of the out of print Lyman #3 manual here, it only covers Lyman molds, but it's still a good reference to have.

You can download a PDF copy of the book From Ingots to Target to your computer for future reference http://www.lasc.us/Fryxell_Book_Contents.htm

More information of interest http://www.lasc.us/CastBulletNotes.htm

Why Powder Coat thread

Without rehashing what some have said, it's fairly easy to shoot full house magnum cast bullet loads without using a gas check, however if you're looking for expansion when casting HP pistol and rifle bullets using a softer alloy gas checks will serve a purpose. Glen Fryxell explains in his book the purpose of a gas check and when it's useful in Chapter #10 Gas Checks vs. Plain Base Bullets

Cast bullets in rifle is a whole different ball game when it comes to getting good accuracy and velocity combined, especially when you get into shooting cast bullet at HV in rifles. Rifle like the 30-30 with a slower twist bore can shoot cast bullet as accurately or better than jacketed bullets in the same velocity range as factory ammo while other rifle with faster twist bores accuracy starts going south with cast bullets as the velocity increase because of unseen defects in the bullet which cause wobble and yaw. In a faster twist bore, the bullet spin much faster than in a slow twist bore, so those defects accentuate the wobble and yaw and cause the bullet to become more out of balance and create inaccuracy. Think of it as a tire out of balance and the faster you go, the more vibration it creates. For most rifle with a 1:10 twist bore with some exceptions the useful velocity range will be between 1600 and 2000 fps. Of course, there are lots of variable that will determine that.

My most accurate cast load in my Rem. 30-06 using H-4198 and a NOE .309" 30 XCB 170 gr. powder coated gas check bullet. 5 shots at 50 yds. Average velocity 2992 Fps.

View attachment 1816743

View attachment 1816744

Mosin 1933 M91/30, 5 shots 50 yds.

View attachment 1816745

I used Alox tumble lube for years and years, various formulas and applications. It can be useful for some, especially if you have a mold that drops bullets of a close enough diameter to not need sizing. There are formulations that aren't quite as sticky or smoky, but like agingstudent says, there are those issues. I don't care for the smoke, smell, or stickiness either. Some guys like it though.I am new to shooting lead in rifles. Can I simply load lead bullets like I would a copper bullet? What is Alox?

You wouldn't be interested in trading for some of those .266" bullets, would you? I've been thinking about loading for my Carcano, even pickup up a .268" push-through sizer, but can't justify buying another mold at this time. No worries if you can't, just a thought.Pulled out the RCBS casting furnace to pour some .266 for my 6.5 Swede. It's been a coon's age since I last did this.

Yes, it's my opinion that coating has advanced the use of cast bullets insofar as speed limits and barrel leading are concerned.@JRuby ... This. And furthermore that diameter, hardness (alloy), and lube type might make it so you don't even need a gas check. I hate fiddling with gas checks If I can avoid it.

Powder coating makes cast projectiles more forgiving, I have found proper diameter becoming the more important ingredient in my experience lately. Less fiddly and much cleaner and efficient than lube and gas checks. If you really wanted to you could gas check a powder coated bullet. I did that with 223 and 22-250 for a while. Then I found a same size plain-based mold that worked just as well when powder coated so why bother with the gas checks?

With the lead bullets I shoot in my 35 Rem, I'm pushing them ~2200 (load estimate, not chrony'd). I found no difference in accuracy, checked or not, so I stopped gas checking them.... Then I found a same size plain-based mold that worked just as well when powder coated so why bother with the gas checks?

Once I perfect them, I'll give you a bunch - or loan you the mold.You wouldn't be interested in trading for some of those .266" bullets, would you? I've been thinking about loading for my Carcano, even pickup up a .268" push-through sizer, but can't justify buying another mold at this time. No worries if you can't, just a thought.

I found that rotating the stopper will sometimes stop a dripping bottom drop pot. I also keep a large cookie sheet under my pot to catch drips and spills.Argh,

Pulled out the RCBS casting furnace to pour some .266 for my 6.5 Swede. It's been a coon's age since I last did this.

Thermometer seems busted. The pot thermostat was set at 700°F, the thermometer was reading 900°.

I got the mold to a nice temperature, and the lead temp seemed right, but the flow never made it to the ribbon, just a drip-drip-drip, which of course shows as "melt too cold" in the castings. They all looked like shizzle. I turned up the temp to see if the flow improved, but then the bottom stopper never sealed and it was always dripping.

Since I don't think I've ever cleaned this pot (got it used), I dumped out the lead (~10 lbs worth) and there was funky slag crusted to the bottom. Cannot imagine what -- Tungsten (W) ?

I'll clean it up, get a new pot thermometer, and try it again. Also, cannot find my ceramic blanket to cover the pot for when I'm warming the mold.

The wife got me a new Lee casting furnace a few years ago. Dunno why I'm too stubborn to unbox and use it.

All in all, a frustrating evening.