Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Gold Supporter

- Messages

- 5,628

- Reactions

- 12,024

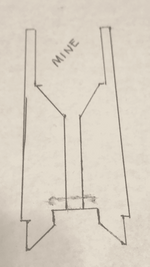

Cell phones are for taking pics of things as you disassemble them. It is intended to be a funnel, so let that guide your reassembly.

- Messages

- 2,499

- Reactions

- 5,708

Bottom pic is right side up

- Thread Starter

- #4

I got the bigger opening end up but it seemed to spill powder. At first, it was OK, then it spilled a little (my charge was 24.0 and about 19-22 left in the case when it's spilled) Then it spilled 1 every 5-10 cases. I machined a more angled cone with a section that hold the case mouth and it doesn't spill any more. I also got powder leakage from the lee auto drum powder measure but got it fixed.

That's not good. Maybe give Lee a call in the morning.I got the bigger opening end up but it seemed to spill powder. At first, it was OK, then it spilled a little (my charge was 24.0 and about 19-22 left in the case when it's spilled) Then it spilled 1 every 5-10 cases. I machined a more angled cone with a section that hold the case mouth and it doesn't spill any more. I also got powder leakage from the lee auto drum powder measure but got it fixed.

Member 5605

- Messages

- 11,671

- Reactions

- 23,700

View attachment 464669 View attachment 464670

I tried to adjust the die up and down many times. It seemed to spill more when I raised it a little. I machined a new powder actuator piece. Made it longer with steeper angle and a section to position the case mouth, problem solved.

Yes, that was/is the problem.

I have the same type of drawing when I had the issue. Lol.

My taper in the bushing was ever so slightly crimping the neck when ran too high. Powder sat on case mouth and would logjam there. Powder everywhere.

Glad you were able to fix it that way.

Bronze Supporter

- Messages

- 19,734

- Reactions

- 55,085

Sounds like something is wrong.

I had issues charging .223 with leakage then I realized I was raising the case too much and was causing some flare making powder ride the rim of the case.

Raised the powder drop a couple of turns and problem solved.

You mean like this, these happened when I was first starting out in reloading with my newly-acquired RCBS single stage press. What can I say I was a newbie.

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

-

-

-

Promoted Radian Model 1 11.5 build. For Trade/Sale

- Started by MrChunkyMonkey

- Replies: 0

-

-

-

-

Handcrafted Leather Wallets. Made to Last from Full Grain Cowhide. Great Price. $20 to $50

- Started by ddjchemist

- Replies: 6

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale