- Thread Starter

- #41

If you're going to be powder coating the hardness will be less crucial and you probably won't need gas checks. It's more important to get the bullet sized properly. If those ingots don't look lumpy and you can scratch or dent them with your fingernail they are likely pure lead or a soft alloy. You can't engrave zinc with your fingernail and it doesn't make an ingot or a bullet worth a darn when it's mixed in with lead.

For cast bullets, not round ball for black powder, I am interested in powder coating - if that also means gas checks aren't needed, that's one less step and that's great.

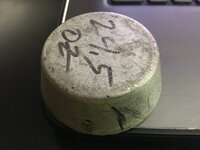

As for the ingots - looks like they were poured into a muffin pan. I did a scratch test on one using both my thumbnail and a key - I was able to scratch the surface fairly easily with both. So, I'm thinking this may be pure lead?

Here are a few photos: