Bronze Lifetime

- Messages

- 61

- Reactions

- 55

While shooting some handloaded 223 rem in an AR, I had one round that did not fire. After ejecting the round, I could see that the primer had a good strike and the head of the case was blackened. Later, I pulled the bullet and found that the case was charged normally. I popped the primer out and confirmed that it did actually go off. The big questions are: 1) why the main charge did not ignite, and 2) why was the head of the case blackened ?

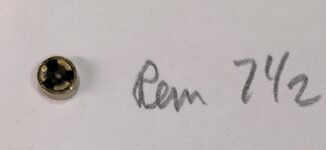

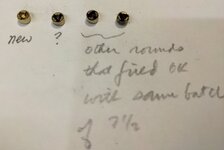

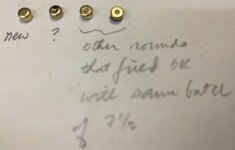

The case had an "FC" headstamp and had been swaged with a Dillon Superswage. The primer pocket and flash hole looked good in every respect and passed the "go" side of a primer pocket gauge. It would not allow the "no-go" end of the gauge to fit in at all. I tried to wipe soot off the case head and clean the flash hole with a Qtip to inspect the metal better. Attached picture is after that. The struck end of the primer was totally clean and I could not see any defects even under a microscope. The charge was 24.1gr N140 under a Sierra 7177. Primer was a Remington 7 1/2. Both primer and powder are fresh.

The case had an "FC" headstamp and had been swaged with a Dillon Superswage. The primer pocket and flash hole looked good in every respect and passed the "go" side of a primer pocket gauge. It would not allow the "no-go" end of the gauge to fit in at all. I tried to wipe soot off the case head and clean the flash hole with a Qtip to inspect the metal better. Attached picture is after that. The struck end of the primer was totally clean and I could not see any defects even under a microscope. The charge was 24.1gr N140 under a Sierra 7177. Primer was a Remington 7 1/2. Both primer and powder are fresh.