- Messages

- 202

- Reactions

- 165

- Thread Starter

- #21

Thank You!

I will check into it...

Larry243

I will check into it...

Larry243

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

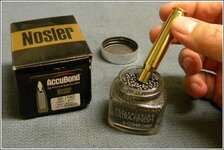

Imperial Dry Neck Lube Convenience Pak - MPN: 07200

It's got small ceramic media about the size of #9 shot in it, you just dip the neck in and done.

View attachment 412015

Neck expansion plays a part in where the bullet meets your lands. If your loading to your chamber's lands or not, consistent expansion of the neck plays a part in how the projectile starts its movement forward into the rifling. If your internal neck it gunked up with junk it won't expand uniformly on the side it has a bunch of junk. If the wall thickness is off, it won't expand uniformly. Key is to have wall thickness as close to uniform as possible for all your ammo to be as close to the same as possible for repeatable results.Thank You,

I am a big Hornady product lover and have been for many years. Although I do use some RCBS stuff, Hornady just does a great job on most products. I use there comparator for everything. Because I am also a big lover of my 6.5 Creedmoor, I do use and shoot Hornady products exclusively except for primers.

Regarding the Case necking issues, I am a firm believer that the retention of the bullet should be in direct contact with the Brass, an not with burnt powder residue or lube.. I have proven to my self through shooting through my Chronograph the bullet ballistics stay closer when they are all cleaned the same. Of course powder has to be very precise. I have no explanation why my groupings are closer, except that retention and bullet release some how does....

Thank's for the neck turning info!

Larry243

That's the stuff I use.Imperial Dry Neck Lube Convenience Pak - MPN: 07200

It's got small ceramic media about the size of #9 shot in it, you just dip the neck in and done.

View attachment 412015

Neck expansion plays a part in where the bullet meets your lands. If your loading to your chamber's lands or not, consistent expansion of the neck plays a part in how the projectile starts its movement forward into the rifling. If your internal neck it gunked up with junk it won't expand uniformly on the side it has a bunch of junk. If the wall thickness is off, it won't expand uniformly. Key is to have wall thickness as close to uniform as possible for all your ammo to be as close to the same as possible for repeatable results.

Neck expansion plays a part in where the bullet meets your lands. If your loading to your chamber's lands or not, consistent expansion of the neck plays a part in how the projectile starts its movement forward into the rifling. If your internal neck it gunked up with junk it won't expand uniformly on the side it has a bunch of junk. If the wall thickness is off, it won't expand uniformly. Key is to have wall thickness as close to uniform as possible for all your ammo to be as close to the same as possible for repeatable results.

I use #7-1/2 lead shot with powdered graphite in mine.Imperial Dry Neck Lube Convenience Pak - MPN: 07200

It's got small ceramic media about the size of #9 shot in it, you just dip the neck in and done.

View attachment 412015

Is that just for the fun of it or did you take the time to measure nermindI use #7-1/2 lead shot with powdered graphite in mine.

Just stab the case neck into it a couple of times, give it a tap on the edge of the container to knock off any excess, and it's lubed inside and out.

Works great and leaves no sticky or hard residue after shooting.

I use #7-1/2 lead shot with powdered graphite in mine.

Just stab the case neck into it a couple of times, give it a tap on the edge of the container to knock off any excess, and it's lubed inside and out.

Works great and leaves no sticky or hard residue after shooting.

This guy does the same thing:Well,

I will have to check it out...

Larry243

Sometimes it's possible to save a few bucks when reloading, but hopefully this won't become your main goal when making handloads. I filled this small bottle with about 5 or 6 ounces of #8 lead shot. Then I mix one tablespoon of powdered graphite into the shot. This inexpensive device helps lubricate the inside of your case necks with great results. Remember to clean the inside of your case necks first with a bore brush. After you do 20 cases, close the bottle and shake it a few times to redistribute the graphite. That supplies the right amount of graphite so you can just dip the neck inside, and give it a twist. This is a quick technique that works well, and it doesn't make a mess.

I still use sized bits of walnut shells and they seem to make the necks come out clean as a whistle but I still run a SS neck brush through them as SOP so never had any trouble (so far).Hey guys...Need to share

I have been a reloader for a few years, and enjoy bench shooting my .243 as well as hunting. I am very particular about loading, and spend extra time making sure my brass is clean, sized, and re-loaded with quality products so I can be assured good groupings and ballistics at the range weekly. I have been researching something that has proven to be well worth the extra effort for better groupings at the range.

Many guys, tumble, size and trim there brass when re-loading and do pretty good...But How many bottle brush the inside of the bullet necks before reloading. When a bullet is fired, there is some baked on residual coatings that will not tumble off when you tumble. The problem is that once you have resized you cartridge necks the coating is still embedded on the brass. This allows a small amount of cushioning that is not pure brass. The press fit process for the bullet is not exactly the same for each round, so the ballistics suffer a bit.

I had been shooting a specific bullet from Hornady for several years with pretty nice groupings... It is the

95 gr SST .243 bullet. I use the same powder and load data to get my 5 round grouping that is 1" to 1.25 with a standard sporting barrel at 100 yds.

The following process now allows me to shoot .875 to 1.0 groupings consistently.

1 Wire brush the case neck with the same brush as your barrel 2-3 strokes is fine.

2 Re-size and extract the primer in the case

3 Tumble until clean and shinny

4 Install new primer

5 Load Powder and Bullet using light anti sizing wax or fluids on external case only

6 The press fit will now be the same on all bullets.... no residual coatings inside exist on the case.

It sure works good for me!....

Larry243

I still use sized bits of walnut shells and they seem to make the necks come out clean as a whistle but I still run a SS neck brush through them as SOP so never had any trouble (so far).