As long as the rounds are passing the "plunk test".

I'm not suggesting you plunk test every round.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

As long as the rounds are passing the "plunk test".

Um..

The bullet seats on the die from the nose. Your die got bumped. The distance from the bottom of the die where it contacts the meplat of the bullet and the top of the shell holder, should be the same.

Unless your press grew, die adjustment was moved, lock ring moved, these distances should be the same.

I can load the same ammo a year apart and get the same results on my die heads without doing adjustments.

if a PLUNK test fails, your new bullets could have a thicker plating, RMR could be using a new die or an old one that's wore out making a little longer lead unit (or shorter for new).

You're talking about splitting hairs. 1.100 is where I run, loads in everything.

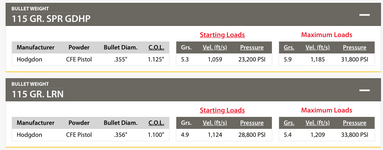

Where is your load data from? I use Hodgdon and theirs shows 1.100".

but.....

View attachment 635391

If you use the Speer Gold Dot Hollow Point of 1.125", your FMJ round nose will be too long causing the issue you've described.

I also use the Hodgdon site for my loading data. But I originally didn't want to run a 1.100 OAL with the plated 115's. I went out to 1.140 and everything was great.

These new FMJ 115's are not nearly as narrow, so I had to drop the OAL to 1.120 to fit them in my barrels. Wish I would have just stuck to the narrower plated ones.

Not sure what pic you are referring to as far as my die "getting bumped"...but it's the second pic I posted that's my actual bullet. The first pic is just one I found on google. Could you explain more what you mean? I only adjusted my dies when I got these new bullets.

That space under the straightedge in your google photo isn't anything I would worry about.

This hour glass shape is the reason I've gone back to a set of steel dies for 9mm that I sometimes use. There are certain forms of what I call case deformation or distortion that carbide dies can impart to brass cartridge cases. The hourglass is one I don't like. Another deformation that results from some carbide dies is the creation of a ridge at the web of the case. Where the sizing process ends. Some will do it, some won't. I've got lots of die sets. They vary enough that sometimes you need more than one set to deal with different brands of cases. I've got three sets of .38 Super, for example.

I just got a carbide sizing die back from Lee. It's from a .40 S&W set. It will leave a ridge in the web of some brands of cases. I have another Lee carbide sizing die from a 10mm set but it's the same part. It never leaves a ridge. So I sent in the die from the .40 set, complaining about the ridge, asking that they polish the carbide ring or whatever to open it up a little. They sent it back with a note saying it was "normal." I guess I will just stick with the 10mm die from the same people, it must be "abnormal" but works better. It isn't just Lee, it's other makes as well.

Of course when you use steel dies, you must use sizing lube, then have the extra step of removing the lube afterward. Usually this is not an issue for me, I'm never in a hurry when I'm reloading. If I'm being lazy, I'll use a carbide sizing die with 9mm. It's not like you can tell much difference when shooting the finished product, one from the other. It's more a matter of pride of workmanship for me.

There is one potential technical issue with the hourglass shape on 9mm. It reduces case capacity, already critical under some conditions of reloading. However slight. But surely no danger under the conditions described in this thread.

Carbide dies is what you want to use. I use Dillon dies for 9mm and 45 acp. Don't worry about the 'bikini' look. Dillon

dies sizes the brass a little more to hold the bullet very firm. I use mostly RCBS standard full length rifle dies for all my semi auto rifles.

223---308---30/06 I have been loading 9 mm on my Dillon for over 35 years.

View attachment 635409

This hour glass shape is the reason I've gone back to a set of steel dies for 9mm that I sometimes use. There are certain forms of what I call case deformation or distortion that carbide dies can impart to brass cartridge cases. The hourglass is one I don't like. Another deformation that results from some carbide dies is the creation of a ridge at the web of the case. Where the sizing process ends. Some will do it, some won't. I've got lots of die sets. They vary enough that sometimes you need more than one set to deal with different brands of cases. I've got three sets of .38 Super, for example.

I just got a carbide sizing die back from Lee. It's from a .40 S&W set. It will leave a ridge in the web of some brands of cases. I have another Lee carbide sizing die from a 10mm set but it's the same part. It never leaves a ridge. So I sent in the die from the .40 set, complaining about the ridge, asking that they polish the carbide ring or whatever to open it up a little. They sent it back with a note saying it was "normal." I guess I will just stick with the 10mm die from the same people, it must be "abnormal" but works better. It isn't just Lee, it's other makes as well.

Of course when you use steel dies, you must use sizing lube, then have the extra step of removing the lube afterward. Usually this is not an issue for me, I'm never in a hurry when I'm reloading. If I'm being lazy, I'll use a carbide sizing die with 9mm. It's not like you can tell much difference when shooting the finished product, one from the other. It's more a matter of pride of workmanship for me.

There is one potential technical issue with the hourglass shape on 9mm. It reduces case capacity, already critical under some conditions of reloading. However slight. But surely no danger under the conditions described in this thread.

Carbide dies is what you want to use. I use Dillon dies for 9mm

My Dillon tool head for 9mm contains a Dillon carbide sizing die and it gives a minimum of "hourglass" distortion.

damon32382, look at the picture ron put in his post. Look at the whiteboard with load data of the moment on it. Check out his 115 gr. 9mm load. Short OAL because the XTP bullet is fairly short. But with that long bearing surface that tends to enhance accuracy.

A little on the hot side, probably cause I kept the powder charge the same,

I used to know a guy who never seemed to have enough work bench space. So he built a new shop and in it he had 70 feet of countertop work surface. And the last time I visited him, he had every square inch covered with disassembled car parts, carbs, generators, starters, electric window motors, etc. Kind of a spacial version of the old economics addage, "Work expands to fill the time alloted." The more space you have, the more you fill it up.

I don't have the bench space. I take the carb off the mower and put just the carb on the bench.

Well I don't either. But I also don't have the strength to lift it up there! Any more.I don't like crawling around on the ground to do that

Well I don't either. But I also don't have the strength to lift it up there! Any more.

I run all mine through a lee factory crimp die and it just squeezes the whole damn round to spec-

Most people think the Lee FCD reduces neck tension due to disparate spring back of the case and bullet.I have wondered about this. I am aware of the Lee Factory Crimp Die for pistol cartridges. I may even have one somewhere, seems like I remember getting one with some other stuff. What I wonder about is the increased friction between the bullet and the inside wall of the case mouth. We always like good bullet tension in reloaded ammo. BUT. I don't remember the proper technical words used, but the more friction that exists between bullet and case brass, the more resistance that is given to the burning propellant at the moment of ignition. In other words, if the bullet doesn't want to go, it resists the power of the burning propellant. Which means pressures can rise due to excessive friction before the actual release of the bullet occurs. Just something to think about, don't know that it's ever been a practical problem.

Some of the thickest (and weakest) brass I've ever encountered was AMERC. So you take something like a plated or these days a coated bullet that tends to be a little on the fat side, then stuff it into an AMERC case, then swage it down (that's what you're doing, I know that word) with a LFCD for pistol, it's gonna be just this side of dynamite. Especially 9mm.

AMERC brass as I've said was overly thick. But it was weak. And that's why it was thick, to compensate for weakness. That's all I can figure. The fired cases with a bubble near the head that had been fired in pistols having barrel designs that didn't fully support the case head, that was routine with AMERC. By the way, Lee also makes a tool for smoothing out those bubbles in cases. Lee Bulge Buster. But some people don't think those bubbled cases would be reloaded again. They say once deformed that way, the brass is compromised. In other words, pushing it back into something like it's original shape doesn't completely "heal" it in terms of strength. More metallurgy terms that I don't remember. Often I can remember a basic concept but not all the terms and details.

Why does the thickness of brass vary from one brand to another? Small to middling size ammo manufacturers mostly don't even make their own cartridge cases, they buy from someone else. So for discussion, I'll just keep to the majors. They have large enterprises with large machines and assembly lines to make ammo. They adjust their machines to operate to certain standards. Take Remington, for example. My experience is that their .45 ACP cases are the thinnest. I save them for fatter bullets. But why are they thinner? Well, they use approx. .451 bullets but their machines are set to work with thinner brass cases which work perfectly fine with their own equipment. But they aren't using (for example) RCBS dies, they are using some proprietary dies that run tighter to use their own brass. Thinner brass times millions and millions of rounds means money saved on material.