Only problem with that, is that I am loading so much pistol ammo, I have no idea how many times it's been reloaded. Mixed range brass, processed by the 5 gallon bucketload. ( not full all the way, usually, but half a bucket of 9mm or .45 is a fair bit of brass.) It gets loaded til it splits, or the primers won't stay put. With match shooting, on the autoloaders at least, I think the competitors end up trading a lot of brass back and forth, since your empties go everywhere and aren't recovered. At least not the same day.Number of times fired is also something to consider in your labels.

Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Only problem with that, is that I am loading so much pistol ammo, I have no idea how many times it's been reloaded.

You're right about this. It's a rare thing for me to keep account of x fired for pistol brass. Only my new .41 Mags get that. The working pressures of most pistol brass are significantly lower than centerfire rifle that they typically last longer and will endure more firings.

Some people loading higher pressure pistol might keep track, things like, .460 S&W, .500 S&W, others. Even maybe 10mm Auto (not me cause I don't shoot them in a Glock).

- Messages

- 783

- Reactions

- 511

I reloaded the toilet paper in the downstairs bathroom. It is Taco Tuesday after all.

- Messages

- 193

- Reactions

- 265

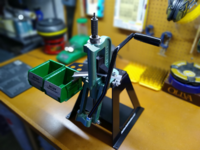

My first loads ever.

Made up some 115gn 9mm. Mostly 4.3-4.4gn of Vithavuori n320 (max 4.5), and made up some 3.9gn as well to see if it would cycle my Extar EP9.

Brass were part range pickup and part once fired Winchester white box.

Bullets are 115gr RN from RBS ammo in Washington.

Primers are Winchester that a NWFirearms member was amazingly kind to reach out to me and sell me when I was just realizing that there are no primers on earth.

Doing it all cheap and dirty. Dry tumble, lube, and into the press it goes. I discovered the re-sizing die has a tendency to SHAVE off parts of the case mouth and drop it to the bottom of the case right as it is going into the powder station. Glad I caught that. Fix seems to be that I have to chamfer/ream every case before it starts the process. That will slow things down a bit, but not horribly. And it also means I have to touch and inspect every case before it hits the press, which I should be doing anyway.

All on my new Lee Loadmaster 5 station progressive.

You get bonus points if you recognize the bottle and know what it is normally used for.

Made up some 115gn 9mm. Mostly 4.3-4.4gn of Vithavuori n320 (max 4.5), and made up some 3.9gn as well to see if it would cycle my Extar EP9.

Brass were part range pickup and part once fired Winchester white box.

Bullets are 115gr RN from RBS ammo in Washington.

Primers are Winchester that a NWFirearms member was amazingly kind to reach out to me and sell me when I was just realizing that there are no primers on earth.

Doing it all cheap and dirty. Dry tumble, lube, and into the press it goes. I discovered the re-sizing die has a tendency to SHAVE off parts of the case mouth and drop it to the bottom of the case right as it is going into the powder station. Glad I caught that. Fix seems to be that I have to chamfer/ream every case before it starts the process. That will slow things down a bit, but not horribly. And it also means I have to touch and inspect every case before it hits the press, which I should be doing anyway.

All on my new Lee Loadmaster 5 station progressive.

You get bonus points if you recognize the bottle and know what it is normally used for.

- Messages

- 1,136

- Reactions

- 1,122

A bunch of 6.8SPC.

My first loads ever.

Made up some 115gn 9mm. Mostly 4.3-4.4gn of Vithavuori n320 (max 4.5), and made up some 3.9gn as well to see if it would cycle my Extar EP9.

Brass were part range pickup and part once fired Winchester white box.

Bullets are 115gr RN from RBS ammo in Washington.

Primers are Winchester that a NWFirearms member was amazingly kind to reach out to me and sell me when I was just realizing that there are no primers on earth.

Doing it all cheap and dirty. Dry tumble, lube, and into the press it goes. I discovered the re-sizing die has a tendency to SHAVE off parts of the case mouth and drop it to the bottom of the case right as it is going into the powder station. Glad I caught that. Fix seems to be that I have to chamfer/ream every case before it starts the process. That will slow things down a bit, but not horribly. And it also means I have to touch and inspect every case before it hits the press, which I should be doing anyway.

All on my new Lee Loadmaster 5 station progressive.

You get bonus points if you recognize the bottle and know what it is normally used for.

View attachment 776621

ive never had that problem that I know of nor have I had it effect results, and I have loaded....a LOT of 9mm. I'm a fan of universal, 700x (not a powder for beginners), and hp38

couple questions if you dont mind, why are you lubing cases? Are your dies not carbide?

ive not used that powder before but I can almost bet your smaller load will absolutely cycle your pistol, experimenting is part of the great fun of reloading!

I should add that I load on a Lee progressive press, the pro4000 or Breechlock pro (same press different marketing)

My wife uses those lids on breast milk bottles.My first loads ever.

Made up some 115gn 9mm. Mostly 4.3-4.4gn of Vithavuori n320 (max 4.5), and made up some 3.9gn as well to see if it would cycle my Extar EP9.

Brass were part range pickup and part once fired Winchester white box.

Bullets are 115gr RN from RBS ammo in Washington.

Primers are Winchester that a NWFirearms member was amazingly kind to reach out to me and sell me when I was just realizing that there are no primers on earth.

Doing it all cheap and dirty. Dry tumble, lube, and into the press it goes. I discovered the re-sizing die has a tendency to SHAVE off parts of the case mouth and drop it to the bottom of the case right as it is going into the powder station. Glad I caught that. Fix seems to be that I have to chamfer/ream every case before it starts the process. That will slow things down a bit, but not horribly. And it also means I have to touch and inspect every case before it hits the press, which I should be doing anyway.

All on my new Lee Loadmaster 5 station progressive.

You get bonus points if you recognize the bottle and know what it is normally used for.

View attachment 776621

Bunch of ttsx monolithic 308 with different charge weights/powders to try.

- Messages

- 193

- Reactions

- 265

Nailed it! Breastmilk bottles!

And yes. Carbide dies. I guess I lube (lightly) because I have the lube. The Lee guy didn't blink an eye at it.

And yes. Carbide dies. I guess I lube (lightly) because I have the lube. The Lee guy didn't blink an eye at it.

- Messages

- 6,824

- Reactions

- 17,613

Nailed it! Breastmilk bottles!

And yes. Carbide dies. I guess I lube (lightly) because I have the lube. The Lee guy didn't blink an eye at it.

Some people lube pistol cases, some don't. I don't. Neither is wrong with carbide dies. Non-carbide requires lube of course.

- Messages

- 2,641

- Reactions

- 3,170

My first loads ever.

Made up some 115gn 9mm. Mostly 4.3-4.4gn of Vithavuori n320 (max 4.5), and made up some 3.9gn as well to see if it would cycle my Extar EP9.

Brass were part range pickup and part once fired Winchester white box.

Bullets are 115gr RN from RBS ammo in Washington.

Primers are Winchester that a NWFirearms member was amazingly kind to reach out to me and sell me when I was just realizing that there are no primers on earth.

Doing it all cheap and dirty. Dry tumble, lube, and into the press it goes. I discovered the re-sizing die has a tendency to SHAVE off parts of the case mouth and drop it to the bottom of the case right as it is going into the powder station. Glad I caught that. Fix seems to be that I have to chamfer/ream every case before it starts the process. That will slow things down a bit, but not horribly. And it also means I have to touch and inspect every case before it hits the press, which I should be doing anyway.

All on my new Lee Loadmaster 5 station progressive.

You get bonus points if you recognize the bottle and know what it is normally used for.

View attachment 776621

Nutella?

If I win can I get some SPP's?

- Messages

- 2,641

- Reactions

- 3,170

Well, all this week I've been playing with my Rockchucker and all the cool toys I got for it!

Wednesday I de-primed / resized more HXP brass for my Garand. Thursday I did the same with about 300 .223/5.56 I had laying around, and last night same thing with some .40 cal brass I had saved from years ago. I absolutely LOVE all this stuff from Inline Fabrication. The ergo handle alone is probably the best upgrade of all. It makes throwing the whole stroke of the press so much easier that I wish I had done it years ago.

Wednesday I de-primed / resized more HXP brass for my Garand. Thursday I did the same with about 300 .223/5.56 I had laying around, and last night same thing with some .40 cal brass I had saved from years ago. I absolutely LOVE all this stuff from Inline Fabrication. The ergo handle alone is probably the best upgrade of all. It makes throwing the whole stroke of the press so much easier that I wish I had done it years ago.

Casting day, today! Got in 4 lbs of tin, and 1 lb of antimony, so I can make about 80 lbs of alloy. Been having some issues with plain wheel weight lead not really flowing and filling out the mold as well as I'd like, hence the tin. Shooting for a Brinell hardness of 11. Will see if I can get pics of the process, today. The new thermometer should help keep things on track, too.

@Red98422 , why would you say 700x is not for beginners? I mean, aside from the smell...

@Red98422 , why would you say 700x is not for beginners? I mean, aside from the smell...

Casting day, today! Got in 4 lbs of tin, and 1 lb of antimony, so I can make about 80 lbs of alloy. Been having some issues with plain wheel weight lead not really flowing and filling out the mold as well as I'd like, hence the tin. Shooting for a Brinell hardness of 11. Will see if I can get pics of the process, today. The new thermometer should help keep things on track, too.

@Red98422 , why would you say 700x is not for beginners? I mean, aside from the smell...

I love 700x but it meters horribly with most auto drop measures which is why I try to warn new people off of it.

great economy from the powder and nice recoil impulse, but with my measures I was getting a spread of .7gn

Silver Supporter

- Messages

- 1,427

- Reactions

- 2,528

I love 700x but it meters horribly with most auto drop measures which is why I try to warn new people off of it.

great economy from the powder and nice recoil impulse, but with my measures I was getting a spread of .7gn

Which means 700x is still better than 800x. 800x is still the only powder that I gave up on and lit the remaining pile of it to celebrate the 4th of July years ago. I don't know why people use it. If 800x was all that was available, I would take a break from reloading until anything else was available.

Staff Member

Silver Lifetime

Bronze Lifetime

- Messages

- 7,053

- Reactions

- 8,761

Loaded 50 rounds of 7.62x39 new brass, Hornady 123gr SST's and 24gr IMR 4198. we'll see how they do on deer and coyotes before loading more.

Finished off the last of my 105gr A-max Hornady's for the 243 now onto the Hornady 103gr ELD-X,s for my brother.

Loaded 100 rds 223 with hard primers, 55gr ballistic tips and 25gr 4064 for AR vs varmint fun.

Been loading 9mm and .40 plinkers for the kid also.

Bought some more 243 brass now to load up more 55gr ballistic tip deer/ yote or whatever stuff. I still cant believe how many of these bullets I found when re organizing.

Finished off the last of my 105gr A-max Hornady's for the 243 now onto the Hornady 103gr ELD-X,s for my brother.

Loaded 100 rds 223 with hard primers, 55gr ballistic tips and 25gr 4064 for AR vs varmint fun.

Been loading 9mm and .40 plinkers for the kid also.

Bought some more 243 brass now to load up more 55gr ballistic tip deer/ yote or whatever stuff. I still cant believe how many of these bullets I found when re organizing.

- Messages

- 499

- Reactions

- 765

In the past week I loaded close to 1000 varying rounds - I knew my son was coming into town and we'd be going out.

I loaded 200 230g softball .45 rounds - 400 115g 9mm - 350 .223 Remington

When we did make it out to shoot his AR malfunctioned so we ended up shooting mostly pistols for the day.

I brought more than I reloaded so we were still in good shape.

When we got home we took apart his lower and noticed that his trigger disconnector had broke. It was a drop-in trigger he spent big bucks on so he was bummed that it didn't work when we were out. It has a warranty so I hope the manufacturer treats him well and replaces the unit. I had a spare mil-spec trigger that I installed so he'll be functional until he gets the warranty item resolved.

As a bonus... I have a nice tub of freshly loaded .223 rounds ready to go since they didn't get used up!

I loaded 200 230g softball .45 rounds - 400 115g 9mm - 350 .223 Remington

When we did make it out to shoot his AR malfunctioned so we ended up shooting mostly pistols for the day.

I brought more than I reloaded so we were still in good shape.

When we got home we took apart his lower and noticed that his trigger disconnector had broke. It was a drop-in trigger he spent big bucks on so he was bummed that it didn't work when we were out. It has a warranty so I hope the manufacturer treats him well and replaces the unit. I had a spare mil-spec trigger that I installed so he'll be functional until he gets the warranty item resolved.

As a bonus... I have a nice tub of freshly loaded .223 rounds ready to go since they didn't get used up!

- Messages

- 14

- Reactions

- 16

Just finished up loading 80 rounds of .30-06 ball for my 03A3.

Bronze Supporter

- Messages

- 16,799

- Reactions

- 27,585

Didn't actually reload but I did call up my bullet supplier to fix my order with him. Hopefully, it'll be here by Christmas.

Aloha, Mark

Aloha, Mark

Bronze Supporter

- Messages

- 1,249

- Reactions

- 972

I did the Inline upgrades also and love them!Well, all this week I've been playing with my Rockchucker and all the cool toys I got for it!

Wednesday I de-primed / resized more HXP brass for my Garand. Thursday I did the same with about 300 .223/5.56 I had laying around, and last night same thing with some .40 cal brass I had saved from years ago. I absolutely LOVE all this stuff from Inline Fabrication. The ergo handle alone is probably the best upgrade of all. It makes throwing the whole stroke of the press so much easier that I wish I had done it years ago.

View attachment 776702

Did the LED lighting from them so I can see every charge dump...

Well, all this week I've been playing with my Rockchucker and all the cool toys I got for it!

Wednesday I de-primed / resized more HXP brass for my Garand. Thursday I did the same with about 300 .223/5.56 I had laying around, and last night same thing with some .40 cal brass I had saved from years ago. I absolutely LOVE all this stuff from Inline Fabrication. The ergo handle alone is probably the best upgrade of all. It makes throwing the whole stroke of the press so much easier that I wish I had done it years ago.

View attachment 776702

- Messages

- 1,917

- Reactions

- 4,789

Did a primer count last night of my CCI small pistol primers in both magnum and regular. Down to 3800...

Got a tip on another gun forum about Federal SPP being available for $269 per 5000 with shipping and hazmat included at some firearm shop's website. Went to the site within 5 minutes of the alert and it took another 5 minutes to get on due to server overload. They were all gone.

Got a tip on another gun forum about Federal SPP being available for $269 per 5000 with shipping and hazmat included at some firearm shop's website. Went to the site within 5 minutes of the alert and it took another 5 minutes to get on due to server overload. They were all gone.

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

-

Saiga 12, Izhmash Shotgun, 12 gauge, NIB, never fired. $1000

- Started by ST5565

- Replies: 0

-

-

-

-

Sico ambi lower with larue mbt trigger, b5 stock and radian safety

- Started by jerhine23

- Replies: 0

-

Ruger Single Six 3 Screw w/.22 LR & .22 WMR Cylinders 1967

- Started by hammerstriker

- Replies: 3

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale