Hey mister Rich, sorry your gun blew up. Any chance you or a friend took photos? I'm interested to see the damage you describe.True, the powder was unknown. However I gave a bit of a description of the powder that an in-the-know pistol handloader

might have been able to make a somewhat logical guess. What I really want to know is why it went off. Gun or handload.

The gun is going back to S&W and perhaps they'll have the time to go over it and give me an answer. It truly has the

appearance of a round not being in battery.

Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Looking fo experience on 9MM handloads . . . . .

- Thread Starter Ruger Rich

- Start date

-

- Tags

- experience looking for

Bronze Lifetime

- Messages

- 6,430

- Reactions

- 12,498

Measure the overall (OAL) length as well before disassembling them. See if they were too short or possibly more clues. Glad that you came out ok.OK guys, thank you. I'll do that, pull the remaining two and measure. And I'll post. You're comments are all important to me. I know I made a mistake with anothers handloads. And catching a bit of flack for it, well I deserve that. Lesson learned guys.

Bronze Supporter

- Messages

- 19,728

- Reactions

- 55,079

I too use titegroup but I weight every charge, yeah I don't load 1,000 rounds in a few hours so there's no chance of a double charge on my press.Yup, pull and measure all 3.

I am using Titegroup these days and have to be very careful since a double charge can easily be fit into 9mm cases.

Bronze Supporter

- Messages

- 19,728

- Reactions

- 55,079

I use it but I weigh each charge plus I always look at the amount in the case.And that is exactly why I never use Titegroup anymore.

I use powders that almost completely fill the case as a safety measure.

Gold Supporter

Bronze Supporter

- Messages

- 24,911

- Reactions

- 59,287

Ah, a powder measure. I'm sure all over and double charges are created using one so your statement is confusing.This, it's what I've always known them as.

View attachment 1350281

- Messages

- 4,807

- Reactions

- 5,097

I just switched from unique to bullseye. Very hard to overcharge with unique, but in checking my powder measure wouldn't meter it very accurately. It would vary a little bit, say a tenth of a grain or so. Bullseye is spot on, I still check every so often and visually check the cases in the loading block. It kinda freaks me out that a 3grain powder charge looks so lonely in my 38 special case ( loading 148 grain fully seated wadcutters ). I am a very careful single station press reloader. I try and be very careful because I don't want to sacrifice a gun, or a hand, or an eye to the reloading gods.

Member 5605

- Messages

- 11,671

- Reactions

- 23,700

This ain't the ammo, this is a gun problem.After going over this with some folks at the range it has the appearance of firing when not completely chambered.

Gold Lifetime

- Messages

- 2,572

- Reactions

- 2,061

It's really hard to overcharge a case with using one, either on a single stage or AP press. Only way I've know to double or overcharge with using one is if you charge the same case twice. That's almost impossible with an AP press and for a single stage you'd have to grab the same case twice or lift the handle twice. Both those are maker errors for not checking before seating a bullet. A rule of thumb I've learned and been told is check about every 10 cases to verify correct weight was added within a max target range of +/- 0.2gr with a target goal of +/- 0.0gr.Ah, a powder measure. I'm sure all over and double charges are created using one so your statement is confusing.

- Messages

- 120

- Reactions

- 259

An interruption a the right moment during single stage reloading can cause a double very easily...

1. handle down to charge round (and bell it perhaps).

2. handle up.

Ding dong...

You return to a case in the press and it is pretty easy to just go right back to step 1 and then continue with the next round.

This is where Titegroup or other high density powders get you. All good as long as you make 100% sure that you always visually check all the loads in the loading block. I *have* found a double when checking a block of 50. It was easy to see when using good light, but you *have* to check.

This discussion has me thinking that I should add a check list to my process and list any step that I want a 100% certainty on.

P.S. Note that *any* powder can suffer from a non-charge with a similar scenario. Then you have "pop" and "BANG" if you are shooting quickly and don't stop in time to avoid that next round. I don't think that has been asked in this thread: "Are you sure that the round before the KABOOM was not a case of bullet stuck in barrel?".

1. handle down to charge round (and bell it perhaps).

2. handle up.

Ding dong...

You return to a case in the press and it is pretty easy to just go right back to step 1 and then continue with the next round.

This is where Titegroup or other high density powders get you. All good as long as you make 100% sure that you always visually check all the loads in the loading block. I *have* found a double when checking a block of 50. It was easy to see when using good light, but you *have* to check.

This discussion has me thinking that I should add a check list to my process and list any step that I want a 100% certainty on.

P.S. Note that *any* powder can suffer from a non-charge with a similar scenario. Then you have "pop" and "BANG" if you are shooting quickly and don't stop in time to avoid that next round. I don't think that has been asked in this thread: "Are you sure that the round before the KABOOM was not a case of bullet stuck in barrel?".

Gold Lifetime

- Messages

- 2,572

- Reactions

- 2,061

Yeah, it's a lot easier to double charge when using a single stage. I've made a habit out of checking every case before it goes back in the block as an added safety step.An interruption a the right moment during single stage reloading can cause a double very easily...

1. handle down to charge round (and bell it perhaps).

2. handle up.

Ding dong...

You return to a case in the press and it is pretty easy to just go right back to step 1 and then continue with the next round.

This is where Titegroup or other high density powders get you. All good as long as you make 100% sure that you always visually check all the loads in the loading block. I *have* found a double when checking a block of 50. It was easy to see when using good light, but you *have* to check.

This discussion has me thinking that I should add a check list to my process and list any step that I want a 100% certainty on.

P.S. Note that *any* powder can suffer from a non-charge with a similar scenario. Then you have "pop" and "BANG" if you are shooting quickly and don't stop in time to avoid that next round. I don't think that has been asked in this thread: "Are you sure that the round before the KABOOM was not a case of bullet stuck in barrel?".

Bronze Lifetime

- Messages

- 11,323

- Reactions

- 25,956

I had a kaboom with a 9mm that blew the mag out of the gun. It was due to setback caused by improper crimp on a normal charge of W231.This ain't the ammo, this is a gun problem.

I examined the gun to see if it also possibly fired while not completely returned to battery. I was surprised that it could be fired out of battery. Then I checked *all* my semi-autos.

What I found was that some pistols will allow firing while as much as 1/8" inch out of battery. That might not mean much with a properly supported chamber, but if the gun has a long feed ramp that exposes the case head at the ramp, that 1/8th inch can be catastrophic.

@Ruger Rich , glad you're intact and only the gun and safety glasses were destroyed.

To provide any help other than a WAG, pictures of the powder are needed. "Fine grained almost black" would describe at least four of my pistol powders.

Gold Supporter

Bronze Supporter

- Messages

- 24,911

- Reactions

- 59,287

Machines are machines, they generally work as designed.It's really hard to overcharge a case with using one, either on a single stage or AP press. Only way I've know to double or overcharge with using one is if you charge the same case twice. That's almost impossible with an AP press and for a single stage you'd have to grab the same case twice or lift the handle twice. Both those are maker errors for not checking before seating a bullet. A rule of thumb I've learned and been told is check about every 10 cases to verify correct weight was added within a max target range of +/- 0.2gr with a target goal of +/- 0.0gr.

Inattention and or misunderstanding is the culprit in most all issues with machines.

Gold Lifetime

- Messages

- 2,572

- Reactions

- 2,061

I'd say I'd have to agree with that. It's why I do checks during every loading step.Machines are machines, they generally work as designed.

Inattention and or misunderstanding is the culprit in most all issues with machines.

Bronze Supporter

- Messages

- 570

- Reactions

- 458

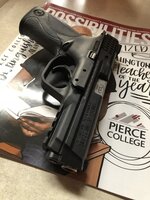

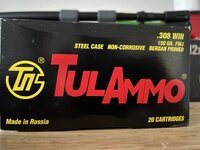

@Ruger Rich I'm glad the situation turned out OK even though you likely shat yourself a little. I've had the exact same scenario occur with a S&W M&P 40 (while using a 9mm Storm Lake barrel that I'd shot many times. This was shooting my own reloads of 115 grain bullets. I started reloading with Unique but found quickly that it doesn't meter well and was extremely dirty. I switched to Ramshot True Blue and my 9mm 115 grain load is 5.7 grains. Your description would be accurate for the True Blue powder but also for many other powders out there. I was also pretty fortunate and got only a small cut to my nose and a VERY numbed hand. Everyone I was with at the range did a little dance when the gun fell from my hand. The 9mm bullet that bulged the slide and cracked the frame back to the grip was the very first shot from that barrel that day. In my case, the brass case is still stuck in the barrel throat and you can see the primer pocket and back of the case mostly blown off. I obviously tried to investigate what happened but ultimately can only guess. My initial thought was that I double-charged but found that a double-charge would overfill the case but it doesn't rule out a "hot" charge. I'm very cautious while reloading and only have 1 powder out at a time so it ruled out incorrect powder type. My best guess to what happened was that the brass I used for reloading had a weakened case in the area where the primer sits. Google-Fu found that there are various manufacturers of brass that are NOT really great for reloading so I carefully check headstamps and remove those from my inventory (these are my "no fly" headstamps for sure but YMMV - FM, AMMOLAND, IMT, TULAMMO, MAXXTECH & AMERC). Another red flag is to look inside the case for previous "sub sonic" rounds as the base internally will be thicker with visible interior turn line (this could cause pressure spike with normal charge due to smaller case volume). Inspecting brass prior to reloading is a MUST to weed out any inferior brass (any questionable goes in the trash).

I did contact S&W regarding the matter and it took over 2 months to get a response (this was pre-Covid) and I finally contacted my FFL who legally destroyed the frame. About 1-2 weeks after I legally destroyed the frame, S&W finally contacted me and their response was "no warranty for reloads" and I could send the frame into them for evaluation. I asked what the results of that would be and they said they would probably offer me a "deep discount" on another firearm (I'd already purchased another M&P in 9mm at that point). I hadn't really expected anything from them to be honest.

Keep in mind that this isn't only related to reloaded ammo. I was at the range with a buddy who was shooting TulAmmo in his brand new M1A rifle in 308. I was next to him when on the 5th round fired, I heard what sounded like the "ting" that a Garand clip makes when it's ejected. He had a shocked look on his face. He told me that he felt hot gasses shoot past his face and we found the magazine floorplate on the ground (item that made the "ting" sound). I think the fortunate thing for him was that all the pressure coming back went down the empty magazine instead of into his face. The steel case was stuck in his barrel and the back of the case was missing. We found it on the ground in a complete circle where it separated at the ejection rim. Contacting TulAmmo, they returned his money, didn't want the remaining 495 rounds returned and would pay for gunsmith fees to remove the lodged case and verify firearm OK (which it was, no damage done other than blowing out the magazine floorplate which was also OK). I pulled the bullets from all the TulAmmo for reloading and measured the powder charges and found there was some variation (more than I'd accept - I'm +/- 0.1 grains or it get dumped back into the hopper) but nothing that I would consider dangerous. The issue is that we will never know what the powder charge was in the cartridge that it occurred in. Can only guess it was overcharged.

Photos show the lodged brass case (still have the barrel), the cracked frame (with first time to the range Crimson Trace laser grip - still works after falling to the ground) and the TulAmmo that had issues for my buddy.

I did contact S&W regarding the matter and it took over 2 months to get a response (this was pre-Covid) and I finally contacted my FFL who legally destroyed the frame. About 1-2 weeks after I legally destroyed the frame, S&W finally contacted me and their response was "no warranty for reloads" and I could send the frame into them for evaluation. I asked what the results of that would be and they said they would probably offer me a "deep discount" on another firearm (I'd already purchased another M&P in 9mm at that point). I hadn't really expected anything from them to be honest.

Keep in mind that this isn't only related to reloaded ammo. I was at the range with a buddy who was shooting TulAmmo in his brand new M1A rifle in 308. I was next to him when on the 5th round fired, I heard what sounded like the "ting" that a Garand clip makes when it's ejected. He had a shocked look on his face. He told me that he felt hot gasses shoot past his face and we found the magazine floorplate on the ground (item that made the "ting" sound). I think the fortunate thing for him was that all the pressure coming back went down the empty magazine instead of into his face. The steel case was stuck in his barrel and the back of the case was missing. We found it on the ground in a complete circle where it separated at the ejection rim. Contacting TulAmmo, they returned his money, didn't want the remaining 495 rounds returned and would pay for gunsmith fees to remove the lodged case and verify firearm OK (which it was, no damage done other than blowing out the magazine floorplate which was also OK). I pulled the bullets from all the TulAmmo for reloading and measured the powder charges and found there was some variation (more than I'd accept - I'm +/- 0.1 grains or it get dumped back into the hopper) but nothing that I would consider dangerous. The issue is that we will never know what the powder charge was in the cartridge that it occurred in. Can only guess it was overcharged.

Photos show the lodged brass case (still have the barrel), the cracked frame (with first time to the range Crimson Trace laser grip - still works after falling to the ground) and the TulAmmo that had issues for my buddy.

Last Edited:

- Messages

- 2,499

- Reactions

- 5,708

Just out of curiosity, did you happen to plunk test those unknown rounds in your chamber first?Last Sunday myself and two good friends made a trip to a local range. Rifles and pistols. I've loaded for rifles but not handguns. I have a S&W 9MM EZ that I've put 300/400 flawless rounds through.

After rifle shooting I shot the EZ. On the first mag the 5th round blew the pistol up, totally destroyed. Boogered up my hand, bruised my cheek bone and chipped the right lens of my safety glasses.

I was a very fortunate guy having those glasses on. I was not so bright shooting handloads that I now realize I don't know where they came from. I only had one mag load (8 rounds) of these. The

rest of the 9MM ammo with me was factory. After going over this with some folks at the range it has the appearance of firing when not completely chambered. I did pull the trigger. There were 3

rounds left in the magazine. Pulling the 115g JHP and measuring the powder showed it contained 5.7 g of a rather fine granular powder almost black in color. I'm interested if someone can

identify the powder based on this description. This could perhaps identify a too hot load. Another thought that I could use some advice on is that I'm aware that a deep seated 9MM can raise

pressure significantly, but I don't know by how much. Any experienced comments are very welcome. Thank you . . . . .

Gold Supporter

Bronze Supporter

- Messages

- 24,911

- Reactions

- 59,287

One thing I don't think of often, nor is it much talked about, let alone conceded to be possible, would be for the primer to have enough grunt to drive a bullet hard into the throat giggity or a ways up the barrel prior to proper ignition of the charge.. which then initiates as an obstructed bore. This might be due to improper powder choice and or degraded powder.

Gold Supporter

- Messages

- 1,536

- Reactions

- 3,369

- Thread Starter

- #37

Good thinking, but I did notJust out of curiosity, did you happen to plunk test those unknown rounds in your chamber first?

- Messages

- 2,499

- Reactions

- 5,708

I'm glad you're okay. I was just thinking that since they were reloads it's possible they were reloaded a bit long for a gun with a longer chamber than yours, or perhaps that your chamber didn't care for whatever bullet profile that particular cartridge had. Having the bullet jammed into the Lands could certainly be an issue. Either by start pressure or by keeping the slide and Bolt not quite in battery. Some guns will still let go of the striker that way. Food for thought. Again I am very glad that you are okay and thank you for sharing this.Good thinking, but I did not

Gold Supporter

- Messages

- 1,536

- Reactions

- 3,369

- Thread Starter

- #39

You're correct, however the EZ is an internal hammer pistolI'm glad you're okay. I was just thinking that since they were reloads it's possible they were reloaded a bit long for a gun with a longer chamber than yours, or perhaps that your chamber didn't care for whatever bullet profile that particular cartridge had. Having the bullet jammed into the Lands could certainly be an issue. Either by start pressure or by keeping the slide and Bolt not quite in battery. Some guns will still let go of the striker that way. Food for thought. Again I am very glad that you are okay and thank you for sharing this.

- Messages

- 2,499

- Reactions

- 5,708

I have a shield so mine is Striker Fired. I don't know if an internal hammer would fire slightly out of battery or almost in battery or not. I have no experience with that platform. I do know however, that if a bullet is jammed hard into the throat or rifling it can be a serious issue.You're correct, however the EZ is an internal hammer pistol

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

Promoted Radian Model 1 11.5 build. For Trade/Sale

- Started by MrChunkyMonkey

- Replies: 0

-

-

-

-

Handcrafted Leather Wallets. Made to Last from Full Grain Cowhide. Great Price. $20 to $50

- Started by ddjchemist

- Replies: 0

-

-

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale