- Messages

- 154

- Reactions

- 96

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I've got a barrel that's .875.

BSF told me that's what it was. Thx. And your other info was a great read. I've now come to find that the only way to make a change is with an adjustable block. I think I'm going to start trying to make my own. The one I bought seems simple enough to copy. I've got 5-7 0.750's and my own mill and lathe. Why not?How do you know that?

Adding an adjustable gas block to an AR means adding an additional maintenance item to your AR.BSF told me that's what it was. Thx. And your other info was a great read. I've now come to find that the only way to make a change is with an adjustable block. I think I'm going to start trying to make my own. The one I bought seems simple enough to copy. I've got 5-7 0.750's and my own mill and lathe. Why not?

I'm a pretty lousy machinist but this is the wrong tool. Also, for what it's worth, for the size and difficulty of measuring a port, digital calipers of this grade are pretty notoriously inaccurate. I like Starrett and enjoy numerous measuring tools of theirs.

Just use a drill bit shank and then caliper that.I'm a pretty lousy machinist but this is the wrong tool. Also, for what it's worth, for the size and difficulty of measuring a port, digital calipers of this grade are pretty notoriously inaccurate. I like Starrett and numerous measuring tools from them.

Nice! Expansion - contraction coefficients within metallurgy. Good stuff. Your the kind of guy that makes coming here a rewarding experience. I know what your talking about and just had not considered it until your post. Of course steel, with all of the variants out there, will do the same but nothing like dissimilar metals. Thanks for the heads up.Adding an adjustable gas block to an AR means adding an additional maintenance item to your AR.

Better to buffer it and spring it correctly.

Stay far away from aluminum gas blocks.

They are junk.

If your barrel and your gas block are of similar materials, they will expand and contract at similar rates, thus maintaining a good gas seal.

Aluminum violates that rule and it is less resistant to erosion.

Here's a company that always gets high marks over on AR15.com for being able to take on unusual AR work like gas port work. Pricing is reasonable.Nice! Expansion - contraction coefficients within metallurgy. Good stuff. Your the kind of guy that makes coming here a rewarding experience. I know what your talking about and just had not considered it until your post. Of course steel, with all of the variants out there, will do the same but nothing like dissimilar metals. Thanks for the heads up.

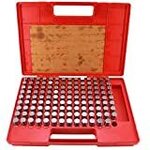

If you were to ask a real machinist how he would measure a small bore, the answer would be "pins".Calipers work.

More of a reference. If you measure .124" and you know standard sizes are .110", .125", .135" etc you can help narrow down. Not a fix all because not everyone uses proper and good calipers.If you were to ask a real machinist how he would measure a small bore, the answer would be "pins".

I've seen the set of precision-ground measuring pins that they use.

Myself, a lowly self-taught Gun Plumber, use the back (shank) of the best-fitting drill bit that I can find and then put the calipers on that. (ghetto pin method)

Trying to make the calipers directly work in a small bore would not be my cup o' tea for me, even at my Gun Plumber level.

Myself, a lowly self-taught Gun Plumber, use the back (shank) of the best-fitting drill bit that I can find and then put the calipers on that. (ghetto pin method)

DD, in my humble and ignorant opinion, is spot on. When I was being taught how to thread a barrel I was told that often the bore is not the center of the barrel and to thread that would cause bad stuff to happen. Hence the pin gauges. These are a set of round little, over priced, little guys that you would insert into the barrel until you find the one that fits snug. Then you center for threading to the gauge. This mandated that the device you intend to put onto the barrel will have a co-witnessed alignment. He is also spot on about the use of drill bits. They do the same thing, as well as drill holes, for a heck of a lot less $$$. So why my post? I have found that many times what is, how it is and how it's done, is not the same as how a "student" machinist would. I was expecting something like, The XYZ of the ABC is the way to know the Dia. of a barrel. More like Djital's vernacular in his response. "gun talk" if you will. You both are awesome resources. Thanks guys!If you were to ask a real machinist how he would measure a small bore, the answer would be "pins".

I've seen the set of precision-ground measuring pins that they use.

Myself, a lowly self-taught Gun Plumber, use the back (shank) of the best-fitting drill bit that I can find and then put the calipers on that. (ghetto pin method)

Trying to make the calipers directly work in a small bore would not be my cup o' tea for me, even at my Gun Plumber level.