- Messages

- 1,065

- Reactions

- 1,059

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

is it normal for the crimp to mark the bullet or is it to much crimp.i set one a little to far and pulled it back out and noticed a mark on the bullet from the crimp.it was noticeable but it didn't break the copper plating.just curious if I have to much crimp.

With your auto cases you just want to remove the flair/bell maybe a tad more. If you have good neck tension that's more important. If the plating isn't cracked it's probably fine but you could back it off a tad. Plunk in your barrel for fit in your gun.is it normal for the crimp to mark the bullet or is it to much crimp.i set one a little to far and pulled it back out and noticed a mark on the bullet from the crimp.it was noticeable but it didn't break the copper plating.just curious if I have to much crimp.

It was to tight,they didn't pass the plunk test because there was a buldge in them.

Yep, this is why the crimp needs the proper adjustment. The die sets have long been made for the proper type of crimp of course. Many seem to want to make everything harder than it has to be for some reason. <shrug>. The people who make the dies of course do know what they are doing. When you set the die all the cases have to have roughly the same length or it will not be consistent. This is why I love the Lee Die for separate crimping. It does away with adjustments and even if the cases are not quite the same you get great crimp. They are not something you need since we were loading long before they were invented. They just came up with a way to make it a lot easier. Since I discovered them they have been a saver for many loaders. Would tell me they were having trouble with loads in one or more of their autos. I would take some of their already loaded ammo and run it past my Lee FC die. Suddenly the ammo would now work. These are certainly not "needed" but if you want the ammo to work and make the loading easy they are the way to go.

I have one for my 9mm and it works great,waiting for my 45 one to get here

've had a batch of them in .357 do that when the cases were too long by a little bit. They didn't pass the ammo checker test but since they were in a revolver I forced them into the cylinder. They shot fine and extracted a little tight.

When crimping/squeezing barely feeling the resistance in the handle of the press is sufficient to close the expanded/belled case mouth on the bullet. That resistance will vary slightly due to varied case lengths.

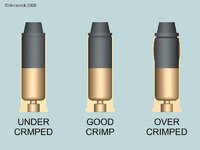

.38, .357, .44 special and magnum, .45 Colt are completely different crimps. Those are roll crimps. We are talking .45 acp, (Arent we?) that is a taper crimp. It's imperative to make sure cases requiring a roll crimp are the same length within about .002" to get uniform crimp on all cases.

Yes.

But.....

Over crimping can cause issues which is the theme of the thread.

The RCBS .45 ACP unit has a very shallow crimp ring where it's 0-100 in a very short span/turn of the die, which as you know is very similar to how a roll crimp is applied. Which is not as forgiving as a taper crimp when using a Lee FCD and its gradual taper vs the short ramp on the RCBS die.

That more clear?

I didn't think there was a ring in a taper crimp die...9mm, .45 etc. Only a narrowing that slowly presses around the case to remove what ever bell is there.

From my experience it takes very little to fold a .38/.357 case....and I don't think I ever folded/bulged a taper crimp cases to the point they were unusable?

And, I'm clear on how to do it. Our poster appears to have it in his mind that you need to REALLY tighten that case around that bullet. That's where the re-quote and the "Maybe I'm missing something" comes from.