- Messages

- 2,948

- Reactions

- 2,214

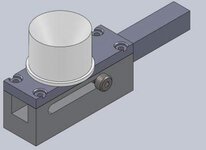

So I'm in the midst of designing a powder measure for one of my pieces of equipment, and I figure it would be pretty easy to add a few modifications to attach it to a stand and sell it as a stand-alone unit, or sell it as a replacement for the powder measures used on normal progressive reloading presses.

I'm using a bushing for setting the quantity of powder. While this is more difficult to fine tune, it is also more consistent and as long as the right bushing is used, nearly trouble free.

I know in the past that bushing type measures have not been popular, however my theory on that is that is mostly due to the fact that they are pretty limited to doing only small pistol powder charges. I was going to size this measure to doing .308 Win and smaller cartridges (~50grs of powder and smaller). Also, it would come with a set of 5 bushings to cover common loads.

I'm machining a prototype right now, however here is the design in solidworks:

I suppose given the configuration of it, it's totally possible to make an adjustable bar, but this may be somewhat out of scope.

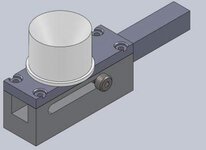

I'm using a bushing for setting the quantity of powder. While this is more difficult to fine tune, it is also more consistent and as long as the right bushing is used, nearly trouble free.

I know in the past that bushing type measures have not been popular, however my theory on that is that is mostly due to the fact that they are pretty limited to doing only small pistol powder charges. I was going to size this measure to doing .308 Win and smaller cartridges (~50grs of powder and smaller). Also, it would come with a set of 5 bushings to cover common loads.

I'm machining a prototype right now, however here is the design in solidworks:

I suppose given the configuration of it, it's totally possible to make an adjustable bar, but this may be somewhat out of scope.