- Messages

- 14,911

- Reactions

- 27,441

Probably a reason why S & W dropped these designs from their lines.It is a Smith and Wesson 340 PD, scandium frame titanium cylinder.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Probably a reason why S & W dropped these designs from their lines.It is a Smith and Wesson 340 PD, scandium frame titanium cylinder.

While I normally get your humor. But this time I have no clue what path you have wondered down. As to passenger capacity the Willys has two seats the rear being given over to carrying camping and adventure gear. The top is structured with 1" sq tubing with mechanical joints with 1/8" Aluminum riveted to the outside then .040" aluminum bonded with JB Weld over that. I would say if properly located it should hold 500lbs. And while I have been married 40 years I have never had a mother inlaw as my wife's mother passed when my wife was just 12.So…. just how many mother in-laws do you suppose that hardtop will hold before it buckles?

I was just checking out the S&W website and it looks like they still make the 340PD and the 340PD w/ no lock. I have had many of these wrist breakers and have yet to break one myself…. That being said, I can imagine that firing .357 mag out of an 11oz alloy that's not even heavy enough to hold down a napkin in the wind, over many a round (not fun), would put a hell of a stress on the scandium frame no doubt.Probably a reason why S & W dropped these designs from their lines.

You THINK you know the mind of Stomper…..While I normally get your humor. But this time I have no clue what path you have wondered down. As to passenger capacity the Willys has two seats the rear being given over to carrying camping and adventure gear. The top is structured with 1" sq tubing with mechanical joints with 1/8" Aluminum riveted to the outside then .040" aluminum bonded with JB Weld over that. I would say if properly located it should hold 500lbs. And while I have been married 40 years I have never had a mother inlaw as my wife's mother passed when my wife was just 12.

Pony wasn't the species in the Equus genus that first came to mind to me!And some of you think I'm a simple-minded one-trick pony….at your own peril!

Looking back in hindsight, that crappy epoxy is the best thing going for the gun.Ok, I have some news..

I just left the pawnshop here on Northeast Sandy, the Silver lining to be exact. Upon further inspection, I took some pictures which I will post here: View attachment 1786550View attachment 1786551

Now, for the the real issue: upon further inspection, I noticed that with the cylinder open, looking up under the barrel from inside the frame, there was a long crack leading from the cylinder out the barrel. At this point, obviously I'm giving the gun back and letting them know, to which they nodded and said they'll let the manager know, then they put it back in the gun case right up top with the price tag. I'm not too sure, but if it was me, I wouldn't have put the gun back in the rack and put the price tag back on it like they did. Be wary and check over your firearms… this one looks like it'll blow up in somebody's hand, should they actually sell it to someone that doesn't catch the crack inside the frame.

I've had JB weld bond to many different materials including Steel and glass and used for years with great success.. the better the preparation, abrasion, degrease of the surfaces, the better the adhesion. Obviously the proper mix proportions are most important.I really am looking forward to a member to reply about an epoxy that will bond with steel. I don't know of one and I have worked with metal and adhesives extensively. JB Weld just doesn't do it. It's more of a filler than a bonder.

There is Loctite but it's not an epoxy, and again its more of a filler.

The magazine attaches to the floor plate so there is much leverage on the hinges when dropping down a full load of rounds.

The magazine attaches to the floor plate so there is much leverage on the hinges when dropping down a full load of rounds.Pony wasn't the species in the Equus genus that first came to mind to me!

Try using JB Weld on a cracked engine block like they used to claim would work.I've had JB weld bond to many different materials including Steel and glass and used for years with great success.. the better the preparation, abrasion, degrease of the surfaces, the better the adhesion. Obviously the proper mix proportions are most important.

While not steel, I tried for years to find a floor plate for a 30-06 BAR to replace one with a broke hinge. I fixed it with JB weld albeit it is a aluminum plate. It held up for years, I then sold it to a friend explaining the issue and he has had it now for years still without issue.

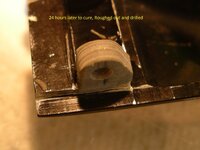

I documented the following, plus more at the time of repair such as drilling, filing, reaming, and finishing but left most out to save space..:

View attachment 1787320

View attachment 1787316View attachment 1787317View attachment 1787318View attachment 1787319 The magazine attaches to the floor plate so there is much leverage on the hinges when dropping down a full load of rounds.

Cast iron is somewhat porous and is almost impossible to clean enough to get anything to stick. About the only way to clean it is to heat it enough that everything burns out. If it was a freeze crack in a water jacket, JB Weld can work, but only if it's clean. (done it) In a combustion chamber or cylinder wall, No F-in way. One of the guys I worked with wasted a bunch of our bosses money (his labor) thinking it would work on a cylinder head where a gasket blew and the engine torched a path between the two combustion chambers... I braze a fair amount of iron, but that's not a job for brazing, either. Welding was the only way to fix that Packard.Try using JB Weld on a cracked engine block like they used to claim would work.

I guarantee you it will not work no matter how well prepared the bonding surfaces.

Learn to weld things like cast iron or steel.

Some things that are broken cannot be fixed with glue.