Member 5605

- Messages

- 11,671

- Reactions

- 23,700

Toss them in the pins. No need to add an extra price or step with walnut. The soap is efficient enough to clean the cases, you'll never know you had anything on them at the end.Thoughts? Ideas? Comments?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Toss them in the pins. No need to add an extra price or step with walnut. The soap is efficient enough to clean the cases, you'll never know you had anything on them at the end.Thoughts? Ideas? Comments?

Toss them in the pins. No need to add an extra price or step with walnut. The soap is efficient enough to clean the cases, you'll never know you had anything on them at the end.

I wet tumble in HOT water with pins and a decent amount of Dawn to get the lanolin out of the inside of the cases.I absolutely plan on running them through a cleaner prior to assembling.

I am trying to decide if i want to run them through a vibratory cleaner with walnut shells prior to throwing in the wet tumbler for a super shiny end-product.

As someone mention previously, the oils tend to get the wet tumbler "dirty" and it needs to be cleaned more often. Cleaning it isn't "THAT" big of a deal, it's just a pain and I don't like scrubbing it out....

I might used the walnut media as the "sacrificial" cleaner. Then I can just dump it and start over with fresh/clean media every-so-often.

Thoughts? Ideas? Comments?

Lanolin Oil USP Grade by Velona - 4 oz | 100% Pure and Natural Carrier Oil | Refined, Cold pressed | Skin, Hair, Body & Face Moisturizing | Use Today - Enjoy Results https://www.amazon.com/dp/B00HZJWYTE/ref=cm_sw_r_cp_api_glc_fabc_34o1Fb9XBKAT3can someone post a link for a place to buy the correct lanolin

Some presses are designed to go over center, with the linkage topping out the ram, and then going slightly past. This means that you have to pull it back to top on your way back down. The engineering principle? Who knows? Maybe a second bump to the sizer, maybe something else. You can both see and feel this if you watch the linkage instead of the case as you size.

You will not notice this by feel if you load with carbide dies and maintain clearance between shell holder and carbide ring when the ram is up. Contact between the shell holder and the carbide insert can fracture the carbide, which is oh so smooth, oh so hard and oh so brittle.

Keep over-center (RCBS and others) linkages lubed up! Those pins undergo an extreme sheering force when the linkage goes over center. Unless you maintain those linkages, they will develop some slack.

Other presses are designed to go to the top and stop. The Lee Classic Cast in one such.

Those tiny little holes can be cleaned with a welding tip cleaner (they're cheap), a pin or needle I suppose, or a high E string from a guitar. If you try a toothpick, you will have quite an adventure when the tip breaks off in the hole. An over-lubed junk case run into the sizer would probably 'hydraulic' it back out, but all we want is clean dies.ALSO!!!! Check and make sure the tiny little vent is free and clear!! And it IS tiny.

This right here.

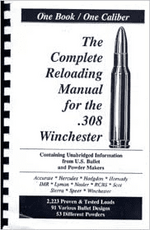

I'm fairly new to reloading. So far I've only loaded pistol. 9mm, 45ACP, 45 SUPER, 44AMP, 357AMP, 50AE. Probably a few thousand rounds total. So, I understand the basics. This is the first time loading for rifle and I'm starting off with .308 Winchester. I have some questions and am hoping for help.

Now I'm ready to continue. But first…..

- I am using an RCBS #15501 .308 Winchester Full Length Reloading Die Set.

- I am trying to process mixed brass. It is mostly LC brass.

- I am using Hornady One Shot spray lube (as that I all I have right now).

- I set up the FL / deprimer die in my Rock Chucker.

- I have an old cookie sheet and lay out 15-20 brass on it. I spray it with the One Shot, and agitate the brass so they roll around and get a coating of lube all over them.

- I grab a shell and insert it into the #3 shell holder and cycle it up to pop out the primer and size the shell. It seems like every LC brass is expanded and is extremely hard to cycle through the sizing die. The other non-LC brass cycles with minimal effort.

- Around the 100th shell (mostly LC, with a few others mixed in) I ripped the rim off a case. Yup! Stuck case! I found on YouTube how to remove it, and thankfully I had the stuff to succeed.

Lube recommendations? Is the "home made" lanolin and rubbing alcohol really "that good"? Does anyone have any suggestions for something that doesn't come in a paste and needs to be applied to each individual shell (like Imperial Sizing Wax).

Am I doing something wrong?

I am open to any and all suggestions.

Why does it seem the LC brass is wider, as it is significantly harder to run through the sizing die?

Thanks & sorry for making this post so long. I wanted to include pertinent info.

Thanks!