- Messages

- 6,824

- Reactions

- 17,613

I got into loading buckshot shotshells last year ( https://www.northwestfirearms.com/threads/shotshell-loading-without-a-press.330826/ ), but ran low on gas seals (though I've since remedied that and have 750 in stock now). That made me wonder just how crucial the gas seal part is, and so I made some test shells.

TLDR: Fail

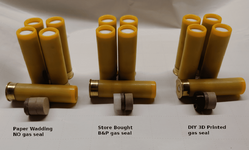

These tests (20 gauge) used 19.8 gr Hodgon Longshot, Fiochi preprimed 2 3/4" shells (low brass), and between 445 and 455 gr. of Remington Buck labeled #3 (except it measures at #4 and is rather inconsistent in size and weight), no buffer, topped with a paper overshot card and roll crimped, the variables being in the wad columns:

Paper Only: 1/8" nitro card and two 1/4" paper wads

Commercial: B&P gas seal, nitro card, one 1/4" paper wad

3D Printed in ABS plastic (*): DIY gas seal, nitro card, one 1/4" paper wad

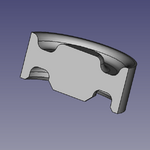

Also pictured are a few of the printed DIY gas seals (my printer is worn out so they look awful) and a cross section of the design:

My DIY gas seal is chamfered rather than filleted on the bottom because of the realities of how my printer prints the first layer. I also made the cut into the bottom of the gas seal a little deeper on the bottom than the top -- my thinking was it would be more likely to expand and seal with longer "legs" so to speak. In the end, a half mm extra didn't matter.

RESULTS - 15 yds, Cylinder Choke:

In the end, the paper wads lost almost 300 FPS over the commercial wads, though accuracy was similar. The 3D printed gas seals totally failed though -- paper wads alone did a better job. The wads I printed in ABS are too stiff and don't give a good seal, although in looking at the one I was able to find, I see scoring marks on the sides so it appears it did contact the barrel at least a little. It is broken --I found it 5 yds from the board and 5' left of center, so I think the odds are better that it hit the board and bounced rather than broke up in the barrel, but without a high speed camera, I'll never know.

Here are some pics of the fired DIY gas seal I was able to find (next experiments will be done in neon orange or some other color I can actually find). In looking at the closeup, top of the picture, you can see how the wall was not straight and especially indented on the powder side, which is also the side that sits on the printer bed. The middle section however, clearly had contact with the barrel though. If I could get the whole thing to do that, the results might be better (but as I keep saying, my printer is worn out).

Anyway -- I'd say this 3D printed seal was a basic failure -- no better than paper and maybe worse. But I think it still deserves some more work, a redesign, and maybe I need to print on a friend's printer.

(*) ABS dissolves in acetone which I figured would be good if I ended up with goo in my barrel given I have acetone. PETG requires nasty stinky bad stuff (compared to acetone) to dissolve. I'm prejudiced against PLA: it's messy and gets all over the nozzle, it's brittle, and it's made with soy or corn or whatever. Soy is for edame and beer and corn is for corn on the cob and beer -- but I want real chemicals in my plastic -- not snowflake marketing. Also I don't know what dissolves PLA and I'm so prejudiced against it, I won't even type the search.

TLDR: Fail

These tests (20 gauge) used 19.8 gr Hodgon Longshot, Fiochi preprimed 2 3/4" shells (low brass), and between 445 and 455 gr. of Remington Buck labeled #3 (except it measures at #4 and is rather inconsistent in size and weight), no buffer, topped with a paper overshot card and roll crimped, the variables being in the wad columns:

Paper Only: 1/8" nitro card and two 1/4" paper wads

Commercial: B&P gas seal, nitro card, one 1/4" paper wad

3D Printed in ABS plastic (*): DIY gas seal, nitro card, one 1/4" paper wad

Also pictured are a few of the printed DIY gas seals (my printer is worn out so they look awful) and a cross section of the design:

My DIY gas seal is chamfered rather than filleted on the bottom because of the realities of how my printer prints the first layer. I also made the cut into the bottom of the gas seal a little deeper on the bottom than the top -- my thinking was it would be more likely to expand and seal with longer "legs" so to speak. In the end, a half mm extra didn't matter.

RESULTS - 15 yds, Cylinder Choke:

Paper | Velocity (FPS) | Pattern Size (in) | | filler columns so the table doesn't go whole page |

1 | 839 | 13.8 | | |

2 | 1140 | 20.2 | | |

3 | 977 | 15.3 | | |

4 | 791 | 16.9 | | |

5 | 896 | 18.2 | | |

ES: | 349.0 | 6.4 | | |

AVG: | 928.6 | 16.9 | | |

SD: | 137.0 | 2.5 | | |

| | | | |

Bought | | | | Poor alignment caused errs for 1 & 2, but the remaining readings are consistent with my previous measurements for the load. |

1 | err | 19.3 | | |

2 | err | 17.5 | | |

3 | 1220 | 13.9 | | |

4 | 1186 | 20.1 | | |

5 | 1226 | 17.5 | | |

ES: | 40.0 | 6.2 | | |

AVG: | 1210.7 | 17.2 | | |

SD: | 21.6 | 3.1 | | |

| | | | |

DIY (**) | | | | I don't believe the readings in shots 1-3. These didn't feel like I should be checking the barrel to see if there was still shot inside. I think I was skewed toward the chrono. |

1 | 265 | 20.8 | | |

2 | 224 | 17.7 | | |

3 | 246 | 16.8 | | |

4 | 621 | 20.2 | | |

5 | 890 | 17.6 | | |

ES: | 666.0 | 4.0 | | |

AVG: | 449.2 | 18.6 | | |

SD: | 295.7 | 1.8 | | |

| | | | |

In the end, the paper wads lost almost 300 FPS over the commercial wads, though accuracy was similar. The 3D printed gas seals totally failed though -- paper wads alone did a better job. The wads I printed in ABS are too stiff and don't give a good seal, although in looking at the one I was able to find, I see scoring marks on the sides so it appears it did contact the barrel at least a little. It is broken --I found it 5 yds from the board and 5' left of center, so I think the odds are better that it hit the board and bounced rather than broke up in the barrel, but without a high speed camera, I'll never know.

Here are some pics of the fired DIY gas seal I was able to find (next experiments will be done in neon orange or some other color I can actually find). In looking at the closeup, top of the picture, you can see how the wall was not straight and especially indented on the powder side, which is also the side that sits on the printer bed. The middle section however, clearly had contact with the barrel though. If I could get the whole thing to do that, the results might be better (but as I keep saying, my printer is worn out).

Anyway -- I'd say this 3D printed seal was a basic failure -- no better than paper and maybe worse. But I think it still deserves some more work, a redesign, and maybe I need to print on a friend's printer.

(*) ABS dissolves in acetone which I figured would be good if I ended up with goo in my barrel given I have acetone. PETG requires nasty stinky bad stuff (compared to acetone) to dissolve. I'm prejudiced against PLA: it's messy and gets all over the nozzle, it's brittle, and it's made with soy or corn or whatever. Soy is for edame and beer and corn is for corn on the cob and beer -- but I want real chemicals in my plastic -- not snowflake marketing. Also I don't know what dissolves PLA and I'm so prejudiced against it, I won't even type the search.