How hard is it to replace the handguard with a newer one?

I want to replace the short quad rail handguard with a slimmer version without all the rails except the top. Can I just order this kit and will have everything I need to swap it?

www.midwayusa.com

www.midwayusa.com

I want to replace the short quad rail handguard with a slimmer version without all the rails except the top. Can I just order this kit and will have everything I need to swap it?

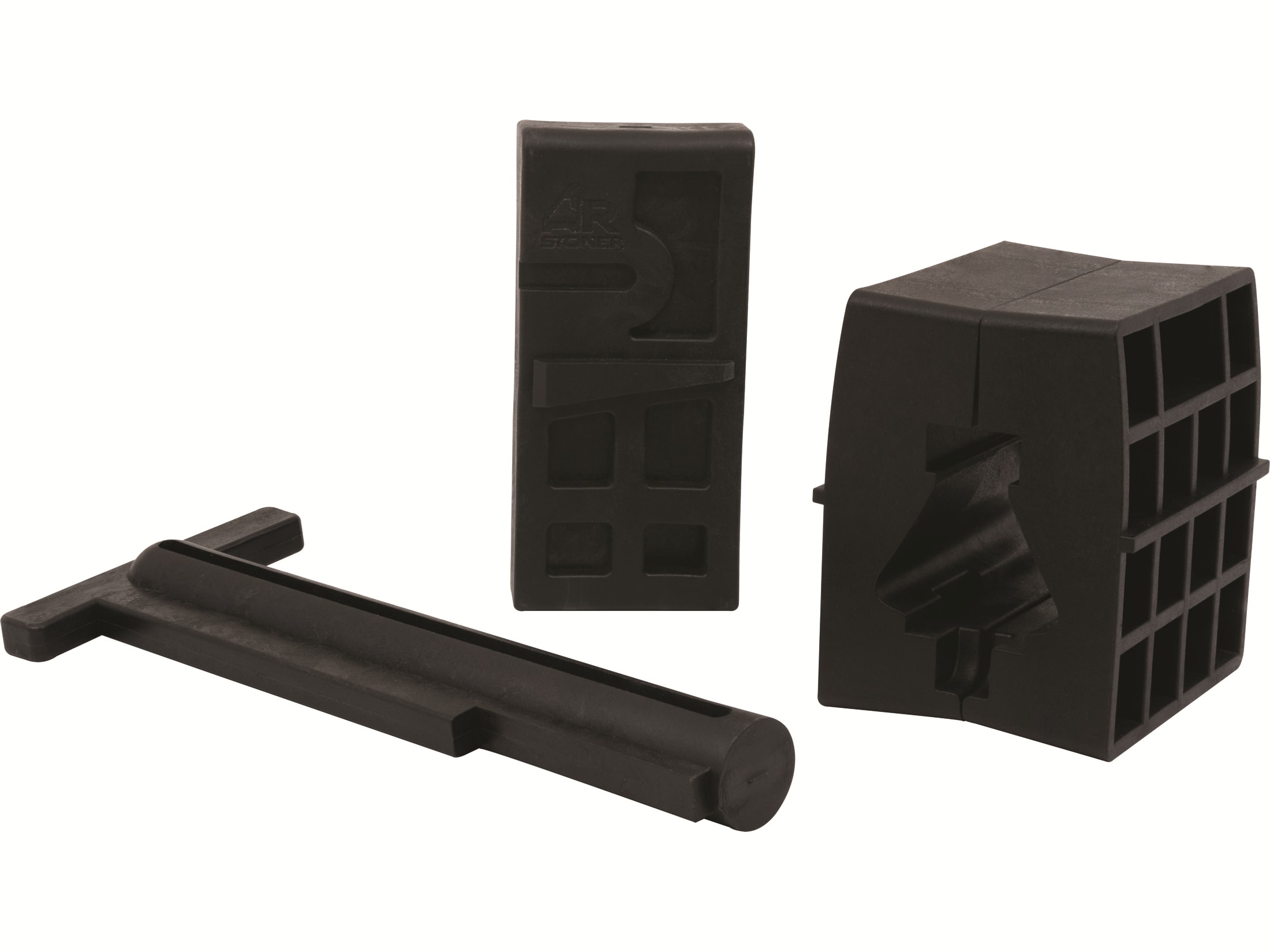

Midwest Industries G4M M-LOK Handguard Gen 4 AR-15 14 Aluminum Black

The Midwest Industries G4M Series Handguards are the perfect option if you are looking for a lightweight M-LOK compatible rail. The super slim 1.5"...