Silver Lifetime

- Messages

- 42,766

- Reactions

- 111,060

I have several rifles that are fairly rare and because of that rarity the market price has increased from well under $1K to $3-6K asking prices. I don't intend to ever sell these rifles - despite the market price, worth too much to me as self-defense SHTF rifles due to their unique configuration and the fact that they were owned before any BGC laws.

None are not NIB, but some are in good shape. One got neglected and due to mice had some rust on it. All of these rifles are almost totally metal (mostly steel, two grips are plastic, one easily removable, one folding and riveted) and have basic cheap blueing so not very rust resistant.

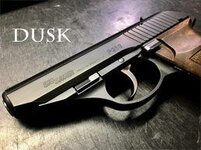

I was thinking of parkerizing them, but then thought about electroless nickel as it . I would like them to be at least a dull matte somewhat dark color (at least greyish). I think the matte would not be a problem, but I am wondering about color - I would prefer black. Do gunsmiths who do electroless nickel plating general have the capability of doing darker colors?

None are not NIB, but some are in good shape. One got neglected and due to mice had some rust on it. All of these rifles are almost totally metal (mostly steel, two grips are plastic, one easily removable, one folding and riveted) and have basic cheap blueing so not very rust resistant.

I was thinking of parkerizing them, but then thought about electroless nickel as it . I would like them to be at least a dull matte somewhat dark color (at least greyish). I think the matte would not be a problem, but I am wondering about color - I would prefer black. Do gunsmiths who do electroless nickel plating general have the capability of doing darker colors?