- Messages

- 69

- Reactions

- 31

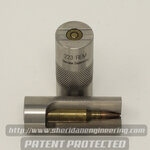

Hello, I'm stuck on an issue I'm having with .223/5.56 reloads. I'm using all LC brass and doing a full resize on all the brass. 55gr bullet no crimp, COL is standard and correct according to reloading manual,. Well once all is said and done, completed round fits in case gauge checker.In a multiple rifles and ar15 platforms it loads fine, but when I go to extract the live round it's a bear to extract. Almost have to motor the rifle while pulling back on the charging handle. Shooting these rounds no issue with extraction. Don't have a clue. Any help appreciated. Thanks!

Last Edited: