- Messages

- 296

- Reactions

- 46

Hey guys,

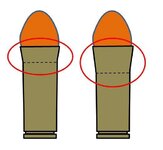

I'm getting ready to do my first reloads (9mm & .40)...I've prepped all my brass...but I'm a little afraid doing it for the first time. I've read my books but am still unsure do I need to crimp the shell casings once I've made the round?

I will be shooting them in semi-auto's....please advise.

Thanks,

I'm getting ready to do my first reloads (9mm & .40)...I've prepped all my brass...but I'm a little afraid doing it for the first time. I've read my books but am still unsure do I need to crimp the shell casings once I've made the round?

I will be shooting them in semi-auto's....please advise.

Thanks,