- Messages

- 578

- Reactions

- 881

Hey NWFS ,

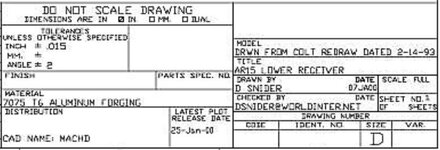

Houston we have a problem !!!!!! So I've been having a trigger issue with my first 80% lower build. The first jig I got was the Anderson's jig , don't waste your time on this jig, it's cheap and not even close to spec. I only purchased it because I have a mill and figured the reference points where good enough for me... Wrong !!!! The trigger pins are off and not getting a solid connection from the disconnect to the sear. If I release the trigger very slowly it fires the trigger and missing the sear completely. Mil-spec this Mil-spec that, lots of junk out their in mil-spec.... So after hours of drinking and hair pulling I bought the nicest jig on the market. The top pin location is good but the front pin is off.

My question is are the large pins .169 in the exact same location as the small pins .154 ?

I really don't want to weld or jb weld or slop a bushing in my lower.

My second 80% lower came out perfect and ended up going with the #23 bit and a .155 reamer. Any of you guys out there using the 5/32 drill bit and don't plan on any coatings or anodized I high recommend the #23 bit and hand ream the finish. Cheaper the anti-walk pins.....

Houston we have a problem !!!!!! So I've been having a trigger issue with my first 80% lower build. The first jig I got was the Anderson's jig , don't waste your time on this jig, it's cheap and not even close to spec. I only purchased it because I have a mill and figured the reference points where good enough for me... Wrong !!!! The trigger pins are off and not getting a solid connection from the disconnect to the sear. If I release the trigger very slowly it fires the trigger and missing the sear completely. Mil-spec this Mil-spec that, lots of junk out their in mil-spec.... So after hours of drinking and hair pulling I bought the nicest jig on the market. The top pin location is good but the front pin is off.

My question is are the large pins .169 in the exact same location as the small pins .154 ?

I really don't want to weld or jb weld or slop a bushing in my lower.

My second 80% lower came out perfect and ended up going with the #23 bit and a .155 reamer. Any of you guys out there using the 5/32 drill bit and don't plan on any coatings or anodized I high recommend the #23 bit and hand ream the finish. Cheaper the anti-walk pins.....