Member 5605

- Messages

- 11,671

- Reactions

- 23,700

So today I decided to get out the Lee Hand Press kit and prepare myself for the next range trip where I plan to go and load rounds at the range for the Remington 700 on some load development etc.

As I placed the shell holder in the hand press I noticed something....

For some background, I have three presses at the house a Lee Breechlock, a Lee Classic Turret and now the hand press. While I have my own personal issues with the Hand Press and BreechLock having different variances of .171" between bases so if you use one, you cannot place the bushing in the other press and expect the exact same results, even if they both are using the bushings.... yeah... well that's another topic.

Upon setting one shell holder into the press I looked over and I still had one of my other .308 shell holders in the breechlock on the bench. Hmmm...

I have two for the .308 base cartridges.

Hornady #1

Lee #2

There was a difference between the two.

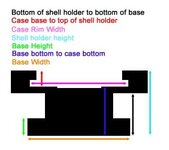

Lee:

Bottom of shell holder to bottom of base: .254"

Case base to top of shell holder: .126"

Case Rim: .479"

Shell holder height: .498"

Base Height: .121"

Base bottom to case bottom: .375"

Base Width: .557"

Hornady:

Bottom of shell holder to bottom of base: .252"

Case base to top of shell holder: .127"

Case Rim: .478"

Shell holder height: .499"

Base Height: .124"

Base bottom to case bottom: .388"

Base Width: .557"

You may ask yourself.. "Why Mr. Dyjital are you making such a fuss out of this?" Take a look at the two measurements that matter how far apart they are:

Lee: .375"

Hornady: .388"

Case base to base of holder.

I'm loading .020" off of the lands. If I ran the wrong base, I would be either .013" closer or .013" further away from the lands. Very important to me when I'm loading in a fixed press vs a turret/progressive/semi-progressive press. I'd hate to be suddenly .007" off the lands or assuming even a .005" margin of error from the ogive and end up with a .002" off lands situation. I do measure every other round when loading this way but this explains a lot.

The last batch of ammo I produced ended up not being the proper length, it was .012" shorter..... Problem found. Issue is now going to be resolved by putting up one of the bases so I don't confuse/switch the two of them.

As I placed the shell holder in the hand press I noticed something....

For some background, I have three presses at the house a Lee Breechlock, a Lee Classic Turret and now the hand press. While I have my own personal issues with the Hand Press and BreechLock having different variances of .171" between bases so if you use one, you cannot place the bushing in the other press and expect the exact same results, even if they both are using the bushings.... yeah... well that's another topic.

Upon setting one shell holder into the press I looked over and I still had one of my other .308 shell holders in the breechlock on the bench. Hmmm...

I have two for the .308 base cartridges.

Hornady #1

Lee #2

There was a difference between the two.

Lee:

Bottom of shell holder to bottom of base: .254"

Case base to top of shell holder: .126"

Case Rim: .479"

Shell holder height: .498"

Base Height: .121"

Base bottom to case bottom: .375"

Base Width: .557"

Hornady:

Bottom of shell holder to bottom of base: .252"

Case base to top of shell holder: .127"

Case Rim: .478"

Shell holder height: .499"

Base Height: .124"

Base bottom to case bottom: .388"

Base Width: .557"

You may ask yourself.. "Why Mr. Dyjital are you making such a fuss out of this?" Take a look at the two measurements that matter how far apart they are:

Lee: .375"

Hornady: .388"

Case base to base of holder.

I'm loading .020" off of the lands. If I ran the wrong base, I would be either .013" closer or .013" further away from the lands. Very important to me when I'm loading in a fixed press vs a turret/progressive/semi-progressive press. I'd hate to be suddenly .007" off the lands or assuming even a .005" margin of error from the ogive and end up with a .002" off lands situation. I do measure every other round when loading this way but this explains a lot.

The last batch of ammo I produced ended up not being the proper length, it was .012" shorter..... Problem found. Issue is now going to be resolved by putting up one of the bases so I don't confuse/switch the two of them.