- Messages

- 40

- Reactions

- 110

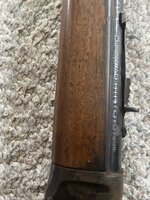

I picked this up (off here with a three way trade of a canoe).

I'm deciding what to do with her. I need the right punches to tear her down, so nothing is happening today.

I figure I'll strip her down. Rub her down with some hoppes I have laying around. Clean off any gunk. OilThen put it all back together and go shoot some cans.

I'll send some after pics, unless someone has a better plan and stops me. Lol.

I'm new to all this.

I'm deciding what to do with her. I need the right punches to tear her down, so nothing is happening today.

I figure I'll strip her down. Rub her down with some hoppes I have laying around. Clean off any gunk. OilThen put it all back together and go shoot some cans.

I'll send some after pics, unless someone has a better plan and stops me. Lol.

I'm new to all this.

![IMG_1705[1].JPG IMG_1705[1].JPG](https://data.northwestfirearms.com/attachments/680/680372-ec5c24727c33ff6171885ab82ce58691.jpg)