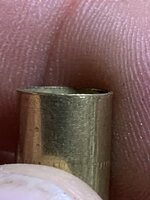

This is what happens when Freedoms dies get out of adjustment or they get a batch of brass that is too short to hit the roll crimp in the die.

I see people on reloading boards all the time tell others that they never trim pistol brass. This is one place that comes back to bite them. A good reliable roll crimp requires the brass to be a uniform length. If you adjust your die for the average length the long ones are going to have too much crimp and the short ones too little. DR

Thank you! I always hear people that never trim handgun brass, and seem to include roll-crimped ammo too.

If they are going to do this, it helps to use brass at least from the same manufacturer, if not the same lot. Mixed brand pistol brass can cause trim issues.

Using single stage equipment, many experienced reloaders don't seat and crimp in the same stroke. They crimp as a second step. If trim issues are present with the brass, you can compensate for this by dialing down the crimp die a bit and do each one by feel. But having that good feel for crimping depth by the each takes experience.

It's well known that revolver-type cartridges should have cannelured bullets and a good roll crimp. Yet some of the pictures in this thread seem to show factory rounds assembled without crimp.

Trim issues do come into play when using already fired who-knows-how-many-times mixed brass. Which is how I started. I deal with it though. I've got the time.

I would like to have it explained to me, so I can understand, how crimping in a separate step from seating eliminates the problem of different length brass? In my mind, a crimp die is set to stop just after optimum crimp is applied. If brass cases differ between .003"-.010" the crimps won't be the same from case to case.

I'd wager it's smokeless powder.

I'd wager it's smokeless powder.