Gold Supporter

- Messages

- 24,546

- Reactions

- 37,219

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Damned straight!I've thrown them at people. Does that make them a projectile?

I agree and there is a much easier method - just cast your own bullets.Interesting, but holy hell, you must have completed EVERY single other task conceivable in life to even consider taking this one on.

I am going to drill out or cut the choke restriction off the barrel. So I should be left with a .410 hole at the muzzle.Both Speer and Hornady in early years made .22 Hornet and .222 Rem bullets using fired .22 LR cases as jacket material. I've bought some home-made bullets of this type at a gun show years ago. So substitute materials can be used, you're only limited by your imagination and the laws of physics.

In years gone by, more people created their own bullets from scratch. I think the old CH company (in Wisc.) was the main provider of materials and equipment. These days, I think Corbin (down Oregon way) is the place to go for such things but you don't enter into that world with the thought of saving money.

Okay, re. firing .410 solid projectiles through a .410 bore shotgun raises the issue of choke diameter. Most inexpensive .410 shotguns I've seen come with a full choke, which is a restriction of +/-.398 in. You wouldn't want to fire a .410 brass projectile through that.

Other .410 bore choke sizes +/-:

Cylinder bore .410

Skeet .404

Imp. cyl. .406

Modified .402

I've never personally seen a Cylinder Bore .410 but no doubt they exist.

The reason you can safely fire lead Foster slugs through a choked .410 bore is because the lead slug is grooved; the grooves compress going through the choke.

Down through the years, bullet swaging supplies and tools have come into my hands. But I always wound up moving them along to another, more ambitious reloader.

The brass should be softer than the barrel steel. If you priced heavy 410 slugs lately, you might be more likely to appreciate the process I am suggesting. It's possible stuffing the bullet in the case and sizing the case could be done in one step with the Lee sizer bushing. The bullet will likely slide into the case easier than the case will slide through the sizer bushing. If a 40 punch was used with the 410 sizer bushing, it would likely push the bullet into the case before the case was forced through the sizer bushing. The 40 cases measure about .424 in diameter, so they will need to be squeezed down about .014. I am not sure how much force that would require but hopefully it could be done in one sizing step.I agree and there is a much easier method - just cast your own bullets.

Even starting from scratch it is easier than this.

Also I can't even fathom the idea of sending brass cases down any barrel of mine as a 'jacket'.

How about this ? Size the case first and then pour molten lead into the case ?It's possible stuffing the bullet in the case and sizing the case could be done in one step with the Lee sizer bushing.

It would produce better results but I have an aversion to firing up my melting pot which is why I tend to shy away from casting my own bullets.How about this ? Size the case first and then pour molten lead into the case ?

It seems this would result in a more uniform projectile overall than messing with 'stuffing' a cast bullet into it.

Only if you use 230 grain 45ACP.....otherwise it's just stripper glitter.I've thrown them at people. Does that make them a projectile?

Use lots of lube. When .330 bullets were scarce, I've resized .338's in one pass without much strain.The 40 cases measure about .424 in diameter, so they will need to be squeezed down about .014. I am not sure how much force that would require but hopefully it could be done in one sizing step.

There are many bullets made with brass jackets. In fact, think of the many that are made with steel jackets. I think here the issue is thickness. Traditional jacketed bullet construction includes a soft lead core. So the jacket material is thin and compresses fairly easily. The thickness of the brass projectile that arakboss proposes would be much greater on the bearing surface.Also I can't even fathom the idea of sending brass cases down any barrel of mine as a 'jacket'.

Yes, it is.The brass should be softer than the barrel steel.

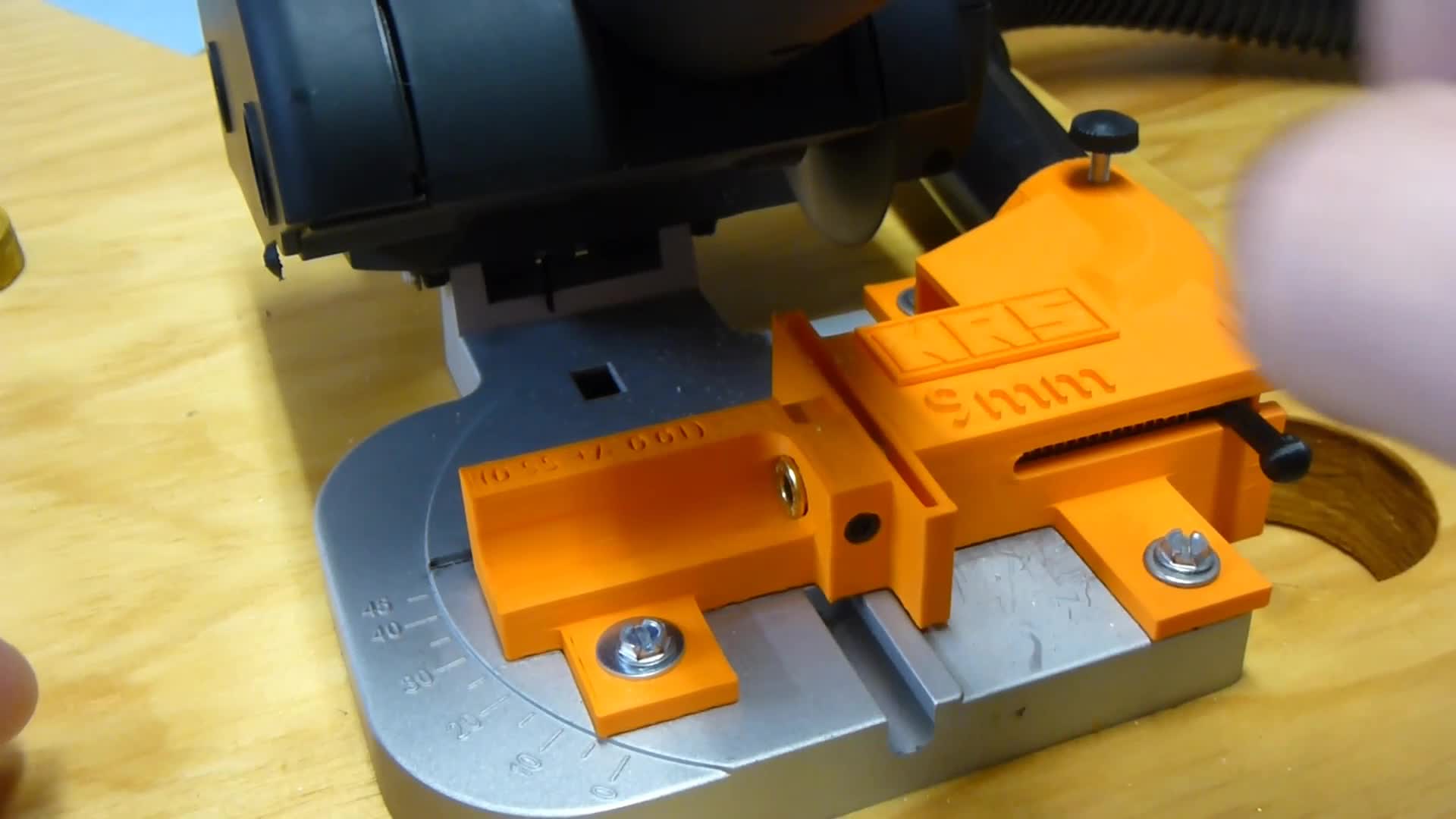

Which is getting into the area of creating a sabot. Which works if done right. Those that are sold commercially use components that are designed for purpose. When I was loading Foster slugs for my 28 gauge, Ballistic Products sold the makings which was a wad, not sabot shells. They worked well enough at closer ranges, like 25 to 50 yards. And considering the sight system on shotguns.As an alternative a 9mm case could be used in the same way without sizing if it was placed in a wad.