- Messages

- 1,917

- Reactions

- 4,789

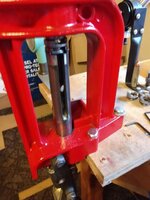

I bought this single-stage press about 8-9 years ago and since day one, noticed that the primers being extracted all shoot out onto the floor and maybe 1 or 2 out of 50 actually go where they're supposed to and end up in the clear hose collector.

It seems like the ram is installed either backwards, or, there is a piece that is missing from the slot in the ram and allows the primers to go the opposite way of the collection thing.

Any ideas? Not a big deal as it has been working fine; it just shoots spent primers on the floor instead of the collection tube.

It seems like the ram is installed either backwards, or, there is a piece that is missing from the slot in the ram and allows the primers to go the opposite way of the collection thing.

Any ideas? Not a big deal as it has been working fine; it just shoots spent primers on the floor instead of the collection tube.