- Thread Starter

- #41

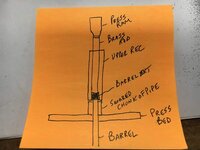

Well I left it in the freezer for 12 hours and just gave it several good whacks on a wooden dowel (plunger stick). All I accomplished was shredding the dowel and getting slivers of wood dust and shavings in the chamber area. No budge. Sounds like a professional job for someone with a press and more experience in building and disassembling AR-15s.