Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Tikka T3x Superlite Barrel threading?

- Thread Starter Gonzales

- Start date

- Thread Starter

- #3

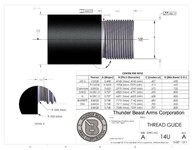

I see that when they offer a threaded model with the lite barrel, it comes with M14x1 threads.

These guys have adapters in M14x1 LH and 9/16-24.

hughesprecision.com

hughesprecision.com

These guys have adapters in M14x1 LH and 9/16-24.

9/16"-24 RH (female) to 5/8"-24, (male) Thread Converter - SKU#062 - Hughes Precision LLC

9/16"-24 RH TPI to 5/8"-24 TPI Conversion Adapter FACTORY DIRECT TO YOU PRICE $19.95

hughesprecision.com

hughesprecision.com

Last Edited:

Silver Vendor

- Messages

- 3,862

- Reactions

- 10,312

I usually thread those 1/2-28

- Thread Starter

- #5

- Messages

- 5,693

- Reactions

- 17,877

I had my Tikka superlight 30-06 threaded 1/2x28 by usmachinegun.com

they will thread it with the barrel attached to the action.

they will thread it with the barrel attached to the action.

- Messages

- 1,223

- Reactions

- 1,715

I would thread it to 1/2x28tpi, Velzey is closer then we are and he does a great job.Anyone try to thread the 6.5 Creedmoor barrel? From my research, most folks cut them down from 24" to 22". I still need to measure my barrel, but here is what I found online.

"The Tikka has a barrel diameter of 0.625" at the muzzle, and 0.635" 1 inch back."

-Matthew

- Messages

- 846

- Reactions

- 1,192

Just my opinion having done one; don't.

Sell it and buy one with a threaded barrel if you really want a threaded barrel.

Sell it and buy one with a threaded barrel if you really want a threaded barrel.

- Thread Starter

- #9

I mostly want to shorten and recrown the barrel. The 24" long barreled Tikka's are a bit nose heavy. The 20" models feel perfect. Figured I'd look into threading it, if there was enough meat on the barrel. I'll pull it out and take some measurements in a few minutes.

Silver Vendor

- Messages

- 3,862

- Reactions

- 10,312

Here is one I shortened a couple and added a Holland brake. Recoil reduction and muzzle jump is all but eliminated even on a t3 lite in 309 win mag.

- Thread Starter

- #12

Gunsmith eyes only. I can remove the external links if needed.

Velzey, what do you think of something like this?

Brake for small contours

Supporting info?

Muzzle Threading — Don't Remove Too Much Steel « Daily Bulletin

"I prefer .150 thousandths barrel wall thickness at the minor diameter of the thread for muzzle brakes because of possible distortion of bore and safe pressure containment. less will work, but only with fitted threads and proper installment.

Barrel makers will say no less than .137 (That an exact engineering dimension) that will cover all pressures generated by different cartridges.

1/2 28 TPI has been used on 30 cal for a long time but even the military has gone to the 5/8 x 24 TPI for safety. Of the muzzle brake failures I have seen, 1/2" x 28 have made up the majority for thread failures. Other failures have been improper installation.

Even threads that have a minor diameter larger than .150 more than the bore wall thickness are recommended when possible to lessen the chance of failure and disturbing the bore diameter.

There are a lot of things that are done and have not caused problems. but how close have they came to catastrophic failure is something we never find out if we are lucky.

J E CUSTOM"

Velzey, what do you think of something like this?

Brake for small contours

Supporting info?

Muzzle Threading — Don't Remove Too Much Steel « Daily Bulletin

"I prefer .150 thousandths barrel wall thickness at the minor diameter of the thread for muzzle brakes because of possible distortion of bore and safe pressure containment. less will work, but only with fitted threads and proper installment.

Barrel makers will say no less than .137 (That an exact engineering dimension) that will cover all pressures generated by different cartridges.

1/2 28 TPI has been used on 30 cal for a long time but even the military has gone to the 5/8 x 24 TPI for safety. Of the muzzle brake failures I have seen, 1/2" x 28 have made up the majority for thread failures. Other failures have been improper installation.

Even threads that have a minor diameter larger than .150 more than the bore wall thickness are recommended when possible to lessen the chance of failure and disturbing the bore diameter.

There are a lot of things that are done and have not caused problems. but how close have they came to catastrophic failure is something we never find out if we are lucky.

J E CUSTOM"

Silver Vendor

- Messages

- 3,862

- Reactions

- 10,312

I figured that's what you were getting to by posting the minimum barrel dimensions.

In years past gunsmiths would turn and thread barrels and distort them all the time. I've had a few in that the first inch was .005 bigger because of poor threading, and turning practices. All the while using high speed steel tooling. Get the steel really how and guess what happens.

Using carbide tooling these days I ( and others) take barrels down to .062 wall thickness.

Never ever have had problems with accuracy or pressure.

When I started threading I always checked the bore with a .0001 dial indicator and gauge pins. Zero distortion.

I have honestly threaded hundreds of barrels the last few years. And have had zero problems

Now that I think about it the Holland tapered quick discharge brakes, at the start of the taper the brake is about .040 thick and tapers out from there. The wall thickness of the threaded area of the brake doesn't exceed .100 or so on some models. They are pretty thin.

In years past gunsmiths would turn and thread barrels and distort them all the time. I've had a few in that the first inch was .005 bigger because of poor threading, and turning practices. All the while using high speed steel tooling. Get the steel really how and guess what happens.

Using carbide tooling these days I ( and others) take barrels down to .062 wall thickness.

Never ever have had problems with accuracy or pressure.

When I started threading I always checked the bore with a .0001 dial indicator and gauge pins. Zero distortion.

I have honestly threaded hundreds of barrels the last few years. And have had zero problems

Now that I think about it the Holland tapered quick discharge brakes, at the start of the taper the brake is about .040 thick and tapers out from there. The wall thickness of the threaded area of the brake doesn't exceed .100 or so on some models. They are pretty thin.

Last Edited:

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

-

-

Large rifle primers and small rifle primers.

- Started by gunsrus001

- Replies: 1

-

-

Atlas-clone Bipods (3) and Pic Adapters

- Started by TwiceOnce

- Replies: 0

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale