- Messages

- 114

- Reactions

- 426

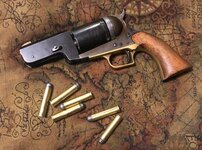

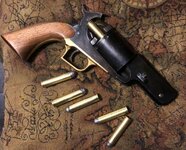

I've been asked to post more of my percussion revolvers converted to fire cartridges. These were quite the thing after the Civil War, when manufacturers had lots of parts for cap-and-ball revolvers on hand, but S&Ws patent on the bored-through cylinder was expiring. Both Colt and Remington factories came out with cartridge-firing versions of their percussion revolvers, but in fact local gunsmiths had been doing such conversions for years.

These days Kirst and Howells offer excellent drop-in conversion cylinders, and gated conversions that require a bit of gunsmithing. These are relatively expensive, and while they are worth every penny that doesn't mean that I can afford them. I've got a pretty decent workshop, though, and a good understanding of metallurgy and reloading, so after buying a couple of conversions I started making my own. One of the conversions that is available is for Colt Walker reproductions. Since '.44' percussion revolvers are actually .45 caliber, the Walker conversions, like other .44 Conversions, use the .45 Colt cartridge... which seems a little weedy for the massive Walker. Originally these revolvers were loaded with a 210gr. bullet over 60gr. of powder, making it the most powerful American revolver until the introduction of .357 Magnum. I figured a more powerful cartridge was in order for the Walker.

I did a little research and found others had been there before me, mostly using reamed-out Kirst Converters with modified .460 S&W brass or something similar. I decided to go a different route. I already loaded .44 Colt, which originally used a .451 heel-base bullet. I decided to do a 'stretched' .44 Colt, again using a heel-base bullet. I checked into 'donor' brass and settled on .303 British as my starting point. I cut the brass and expand it to fit the .451 heel-based 200gr bullet I had been using in .44 Colt, and discovered that the casing would take 55gr. of black powder, so I named the cartridge .44-55 Walker. I procured an Armi San Marco Walker reproduction and went to work.

The revolver, in stock form, weighs 4-1/2 lbs., and has a very long barrel. I decided I wanted something handier, and shortened the barrel to 3-1/2 inches. The dang thing still weighs 3-1/2 pounds! I chucked the culinder in my metal lathe and turned the back of the cylinder down around the sprocket, then bored it through and reamed the chambers to .451. I made a breech-plate from 5160 spring steel, installed a rebounding firing pin and cut a loading port in both the frame and breech-plate. Extraction is accomplished with a separate brass rod; the casings are so long there was no way to mount an ejector with the shortened barrel. The result is a ball to shoot! Recoil is reasonable; the guns 3-1/2lb. weight takes most of the sting out of it.

Here's some pictures-

These days Kirst and Howells offer excellent drop-in conversion cylinders, and gated conversions that require a bit of gunsmithing. These are relatively expensive, and while they are worth every penny that doesn't mean that I can afford them. I've got a pretty decent workshop, though, and a good understanding of metallurgy and reloading, so after buying a couple of conversions I started making my own. One of the conversions that is available is for Colt Walker reproductions. Since '.44' percussion revolvers are actually .45 caliber, the Walker conversions, like other .44 Conversions, use the .45 Colt cartridge... which seems a little weedy for the massive Walker. Originally these revolvers were loaded with a 210gr. bullet over 60gr. of powder, making it the most powerful American revolver until the introduction of .357 Magnum. I figured a more powerful cartridge was in order for the Walker.

I did a little research and found others had been there before me, mostly using reamed-out Kirst Converters with modified .460 S&W brass or something similar. I decided to go a different route. I already loaded .44 Colt, which originally used a .451 heel-base bullet. I decided to do a 'stretched' .44 Colt, again using a heel-base bullet. I checked into 'donor' brass and settled on .303 British as my starting point. I cut the brass and expand it to fit the .451 heel-based 200gr bullet I had been using in .44 Colt, and discovered that the casing would take 55gr. of black powder, so I named the cartridge .44-55 Walker. I procured an Armi San Marco Walker reproduction and went to work.

The revolver, in stock form, weighs 4-1/2 lbs., and has a very long barrel. I decided I wanted something handier, and shortened the barrel to 3-1/2 inches. The dang thing still weighs 3-1/2 pounds! I chucked the culinder in my metal lathe and turned the back of the cylinder down around the sprocket, then bored it through and reamed the chambers to .451. I made a breech-plate from 5160 spring steel, installed a rebounding firing pin and cut a loading port in both the frame and breech-plate. Extraction is accomplished with a separate brass rod; the casings are so long there was no way to mount an ejector with the shortened barrel. The result is a ball to shoot! Recoil is reasonable; the guns 3-1/2lb. weight takes most of the sting out of it.

Here's some pictures-