- Messages

- 2,948

- Reactions

- 2,214

I don't know much about suppressors. To me it seems a lot easier to go with cones, rather than drilling a straight hole 10 inches long.

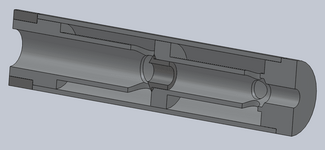

Do it a few times and it's not all that hard. Generally you do a pilot hole, followed by reamers. I also have the ability to do gun drilling, which is why I have a lathe with an 8' bed. I could make a monocore longer than most rifle barrels.

Yeah have a lathe accessible, I've found the ways to do what I need with what I have. Takes an extra step but it doesn't need a more expensive machine.

I'll do some more research regarding flow and such. I have plenty of time to do that.

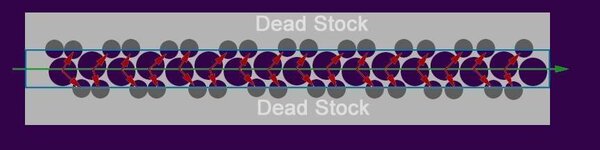

I could draw up the way I plan to do it without cnc, just requires two dead pieces on each side as this will start as square stock and be turned down after the holes are drilled. Easier to work without cnc using squares vs cylinders.

In summation, need to redesign, off set holes, keep same diameter and keep reading.... Maybe find a program to test fluid dynamics.....

Also keep in mind I do this to test the limits of what I can do with what I have. I could just buy an econo-can and make my suppressor screw to the end of that, either way I'm still making my own stuff. (Though not sure of the legality of adding anything beyond the econo-can)

That's an interesting idea (starting flat, turning round) generally lathe work is what tests my patience when it comes to building many things. Lemme see if I can dig out some of the old crankshaft designs I started out with. They're not much more efficient than stacked washers. There are also a number of other modified M-baffle type designs that are much smaller, but less efficient that are great for rifle carbines that can be done with a lathe and drill press.

I'll dig those up and post them later.